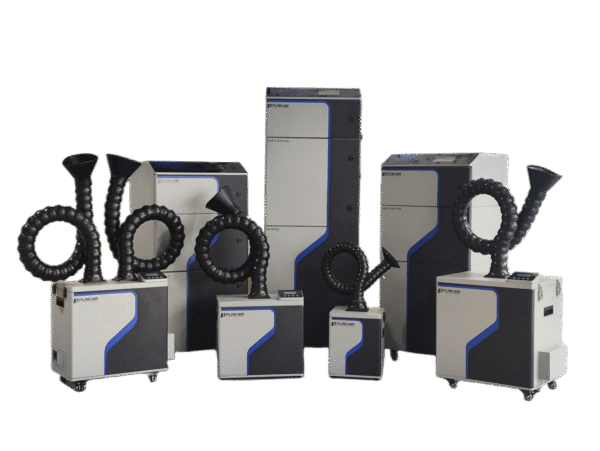

Expert in sticky smoke purification | Save 40% space + self-cleaning filter | [PURE-AIR]

[PURE-AIR] FGS-i series laser smoke purification equipment uses anti-stick pre-filter filter + 10KPa super vortex negative pressure to solve the problem of high-fat smoke clogging, 0.3 micron particle filtration efficiency 99.9%, workshop air direct exhaust compliance!

Applicable scenarios: wood carving smoke, rubber laser cutting odor, two-color plate etching harmful gas