Advanced Industrial Fume Extraction for Safety

The PURE-AIR FS Series gluing and potting fume extractor efficiently removes smoke, odor, and harmful gases generated in industrial processes. Its powerful 9600Pa brushless fan draws polluted air through a three-stage filtration system. Medium-efficiency filters trap large particles, HEPA filters remove 0.3-micron dust, and activated carbon absorbs volatile chemicals. This combination ensures 99.99% purification efficiency, reducing workplace contamination and maintaining a healthier environment for staff.

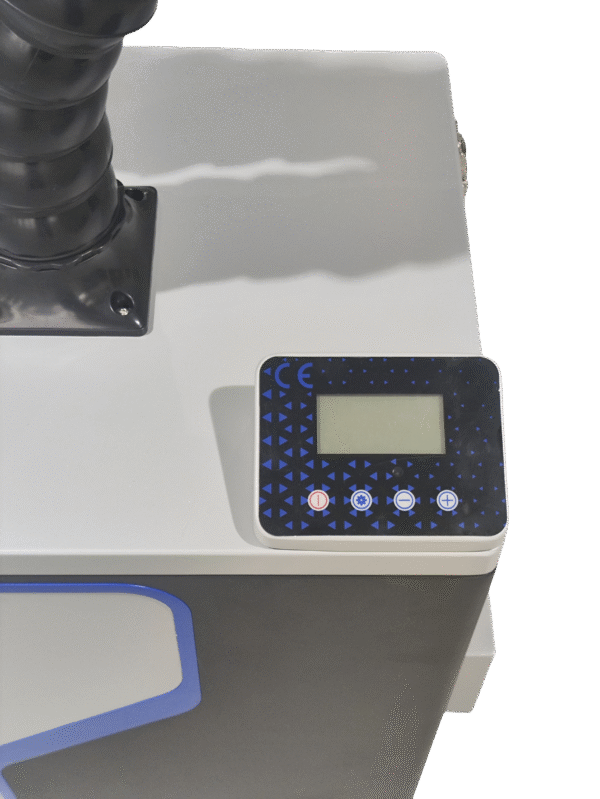

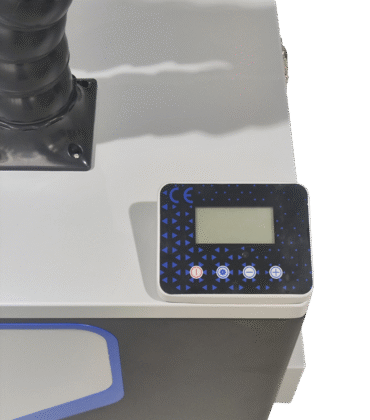

Intelligent Energy-Saving Design

The extractor incorporates smart energy control. Operators can adjust suction power with precision using the intuitive control panel. Ten power levels allow for tailored extraction based on workshop activity and workload. When filters clog, the system triggers dual sound and light alarms, prompting timely maintenance. This proactive design reduces downtime, ensures safety, and saves energy in long production shifts.

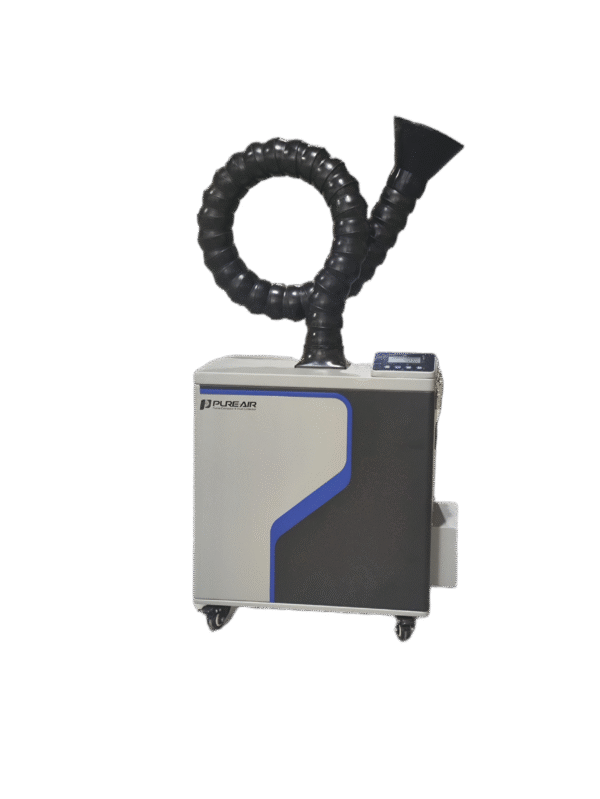

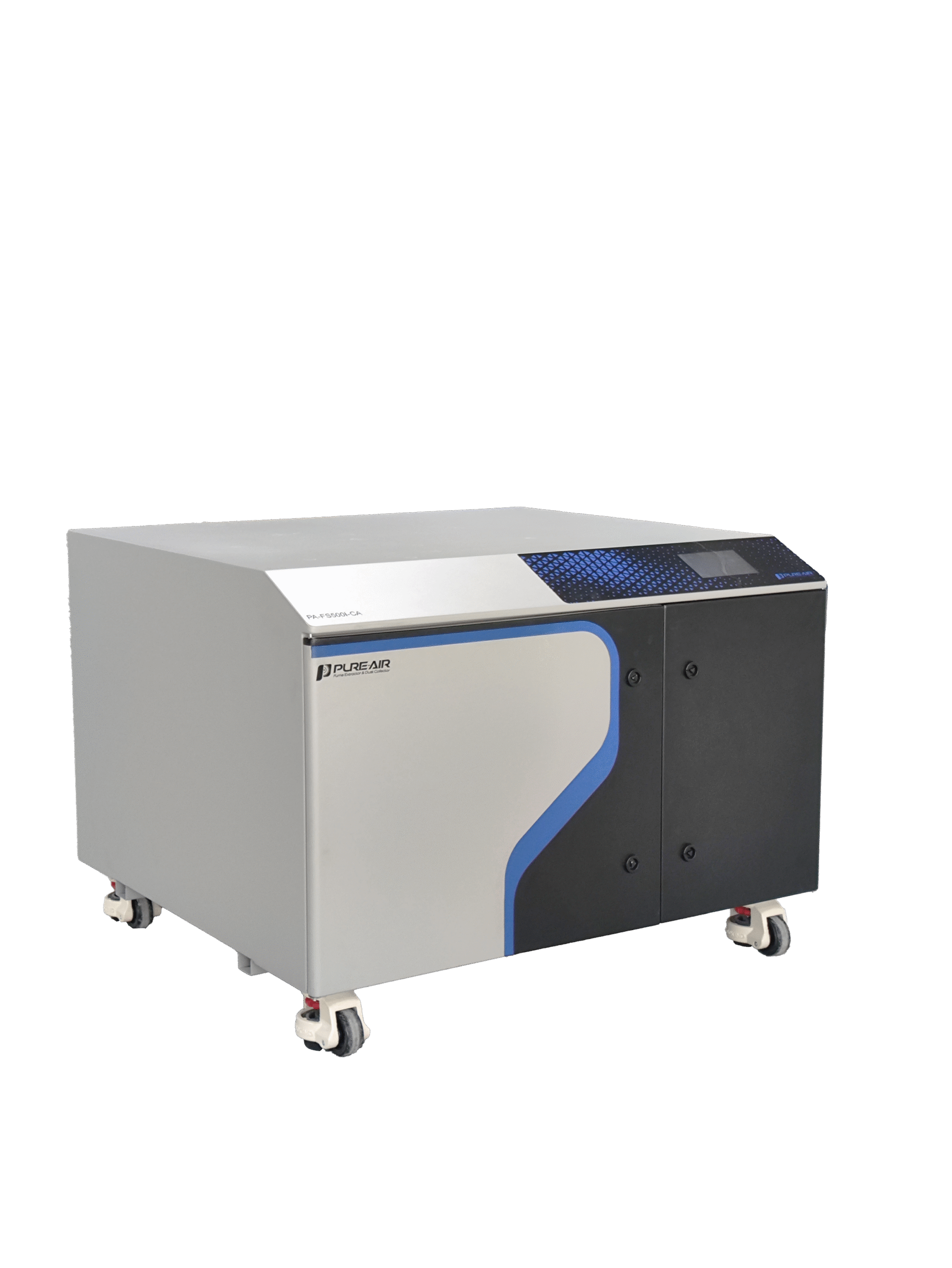

Compact, Portable, and Durable Construction

Despite its high capacity, the FS Series remains compact and mobile. Industrial casters allow quick relocation across the workshop in under five minutes. The robust body houses a maintenance-free brushless motor rated for 30,000 hours. All filter elements are independently replaceable, lowering operational costs by approximately 40%. Operators benefit from durable, easy-to-clean equipment suitable for continuous industrial use.

Multi-Application Capabilities

The extractor is ideal for gluing, potting, and other chemical-intensive processes. Its filtration system captures hazardous fumes from adhesives, resins, and epoxies used in electronics, automotive components, and plastic assembly. The flexible hose and adjustable intake nozzle ensure precise smoke capture at the source. This versatility makes the FS Series suitable for large production floors, cleanrooms, and small-scale workshops alike.

Simplified Integration and Operation

Installation requires minimal effort. The FS Series supports plug-and-play setup with standard electrical connections. LCD displays provide real-time monitoring of airflow, fan speed, and filter condition. Operators can link the extractor to production lines for synchronized operation, improving workflow efficiency. Its quiet operation, with noise levels as low as 65 dB, reduces disruption in busy industrial environments.

Reliable Performance and Workshop Protection

By deploying the PURE-AIR gluing and potting fume extractor, industries can safeguard worker health while meeting environmental standards. The extractor effectively mitigates indoor pollutant exposure, supports safe emissions, and contributes to regulatory compliance. Whether used in electronics assembly, laser cutting, or chemical potting, the FS Series provides consistent, high-performance fume removal that ensures both safety and productivity.