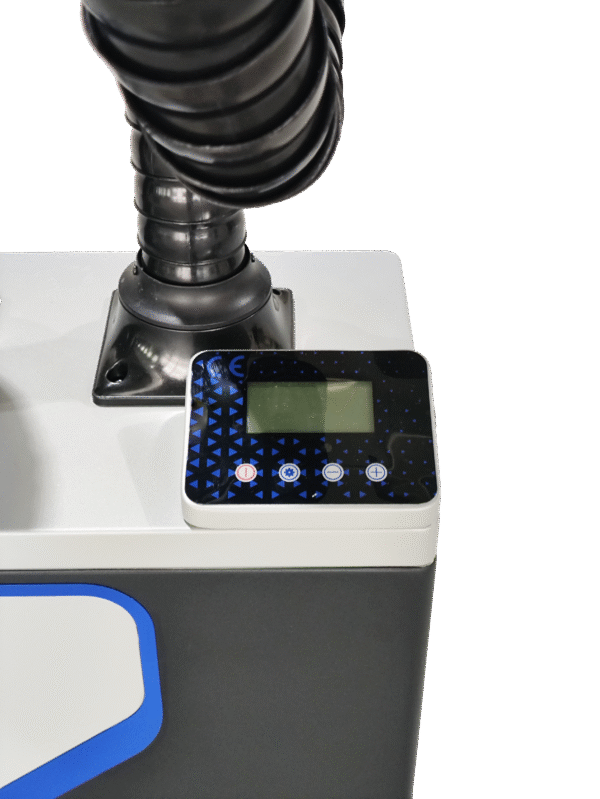

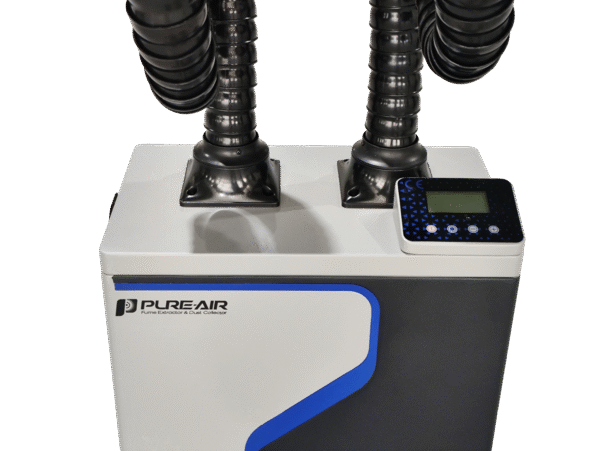

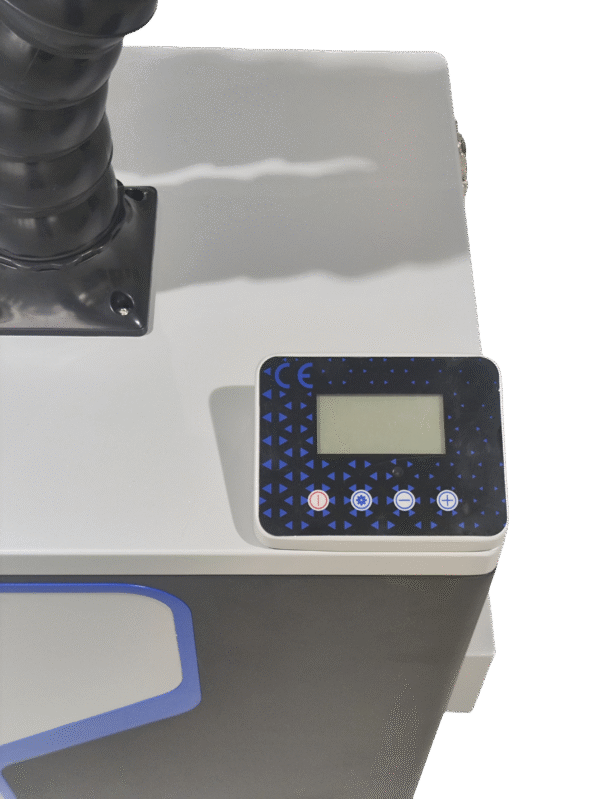

DFS Series Laser Air Purifier Solutions for Gluing and Potting

PURE-AIR DFS laser air purifier solutions provide 99.99% filtration efficiency for gluing and potting industries. With pulse cleaning and strong suction, it ensures safe and clean workshop air. Contact us today for bulk orders and reliable industrial purification solutions.