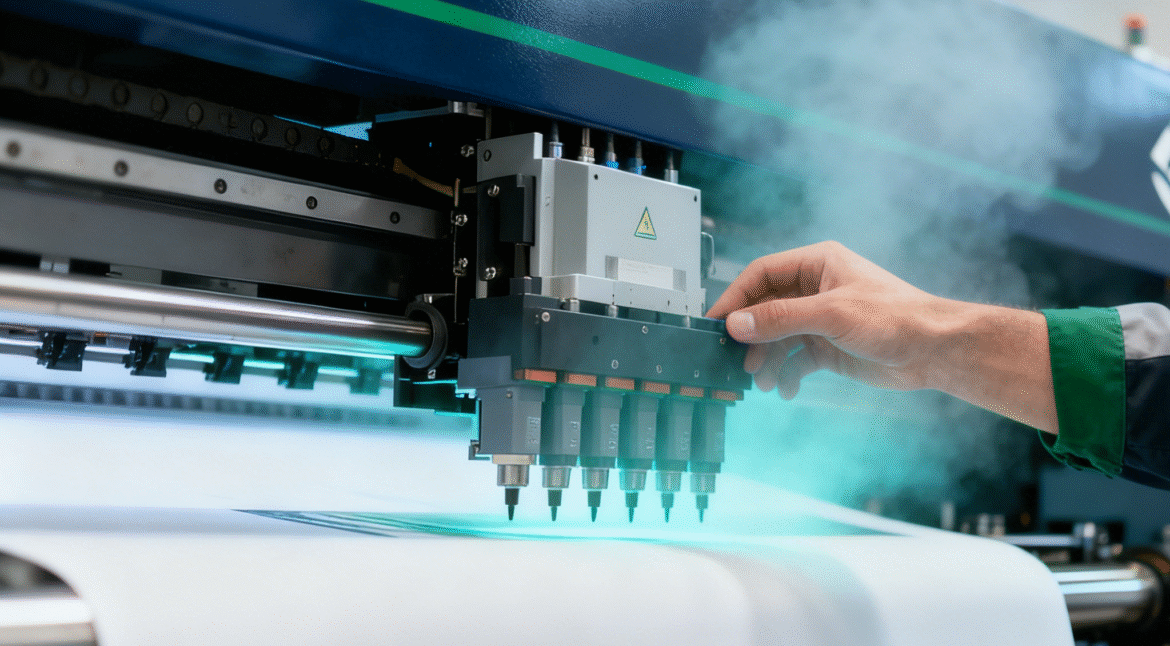

Behind every high-precision industrial process lies a hidden risk. Thermal operations such as laser cutting, welding, and plasma gouging drive efficiency, yet introduce serious hazards. As production continues, workshops can rapidly fill with sub-micron metal dust, carcinogenic gases, and volatile organic compounds. More critically, when fine metallic particles accumulate, they create a silent and catastrophic threat: dust explosions.

To combat these threats, a standard ventilation fan is no longer sufficient. Manufacturers must deploy a sophisticated exhaust fume extraction system designed with a “Triple Defense” philosophy. This system must act as a sniper, precisely neutralizing inhalable particulates, absorbing invisible toxins, and eliminating the physical triggers of explosions. This article explores the engineering architecture of multi-stage filtration and the critical role of explosion-proof design in securing the industrial environment.

1. The Complex Anatomy of Industrial Fumes

Before we can neutralize the enemy, we must understand its composition. Industrial processes do not produce “smoke”; they produce a complex aerosol.

The Particulate Threat

Welding and cutting vaporize metal, which then condenses into ultra-fine particles, often smaller than 0.1 microns. These “sub-micron” particles are particularly dangerous because they bypass the human body’s natural filters and enter the bloodstream directly through the lungs.

The Chemical Threat

High-temperature reactions with coatings, oils, and the air itself generate toxic gases. This includes Ozone from arc welding, Formaldehyde from resin cutting, and Hydrogen Cyanide from certain polymer processes.

The Explosive Threat

Many industrial dusts—including aluminum, titanium, and even certain carbon-based powders—are highly combustible. In a confined extraction duct, the right concentration of these dusts combined with a stray spark can trigger a devastating explosion.

2. Target One: Eliminating Inhalable Particulates with Multi-Stage Filtration

A high-performance exhaust fume extraction system employs a tiered defense strategy. We do not rely on a single filter; instead, we use a sequence of barriers that grow progressively finer.

Stage 1: The Spark Arrestor and Pre-Filter

The first line of defense is the “Spark Arrestor.” In processes like grinding or welding, the system must prevent hot embers from reaching the main filter medium.

-

Mechanism: Using metal mesh or centrifugal force, the system cools and traps sparks and large metal shards.

-

The Pre-Filter: Following the arrestor, a G4 or F7-rated pre-filter captures the “bulk” of the dust (typically particles >10 microns), extending the lifespan of the more expensive downstream filters.

Stage 2: High-Efficiency Particulate Air (HEPA/ULPA)

To capture the dangerous sub-micron smoke, the system utilizes HEPA (H13/H14) or even ULPA filters.

-

Performance: These filters utilize a dense mat of randomly arranged fibers to trap 99.97% of particles as small as 0.3 microns.

-

Action: For heavy-duty industrial use, we often use PTFE-coated cartridge filters. The non-stick surface allows the system to “pulse-clean” the dust into a collection bin, maintaining constant airflow without clogging.

3. Target Two: Neutralizing Toxins through Molecular Adsorption

Particulate filtration removes the “cloud,” but it leaves behind the “smell” and the chemical danger. Gaseous pollutants pass through HEPA filters like air through a screen door. To stop them, an exhaust fume extraction system must employ chemical warfare.

The Power of Activated Carbon

Activated carbon acts as a “molecular sponge.” Through a process called adsorption, the massive internal surface area of the carbon traps VOCs and odors.

-

Surface Area: Just one gram of high-quality activated carbon has a surface area equivalent to several football fields.

-

Chemical Impregnation: For specific toxins like Formaldehyde or acid gases, we use “impregnated” carbon. This carbon is chemically treated to react with and neutralize specific hazardous molecules, turning them into harmless salts.

4. Target Three: Sniper Precision Against Explosion Risks

The most dangerous aspect of a dust collection system is its potential to become a bomb. If the extracted dust is combustible, the exhaust fume extraction system must be built to ATEX or NFPA safety standards.

Anti-Static Engineering

Static electricity is the silent trigger. As dry dust particles rub against the internal walls of a plastic or ungrounded duct, they generate thousands of volts of static electricity.

-

At the core of our safety-focused design lies intelligent static control. We employ conductive filter media reinforced with stainless steel fibers. Meanwhile, every system component, from the suction hood to the motor, remains electrically bonded and grounded. As a result, static charges discharge safely and continuously into the earth.

Explosion Venting and Isolation

If an ignition occurs despite all precautions, the system must protect the building and the workers.

-

Explosion Vents: These are “weak points” designed to rupture at low pressures, directing the force of an explosion upward or outward into a safe zone.

-

Back-Draft Dampers: These valves automatically slam shut if they detect a pressure wave, preventing the explosion from traveling backward through the ductwork to the worker’s station.

-

Flame-Retardant Media: All filter elements should utilize flame-retardant coatings to ensure that the extraction unit itself does not become fuel for a workshop fire.

5. Smart Monitoring: The Brain of the Extraction System

Modern systems no longer rely on guesswork. They utilize a digital “nervous system” to ensure all three defenses are active.

-

Pressure Differential Sensors: The system monitors the “push and pull” across the filters. If a filter is clogged, the system alerts the operator or automatically increases motor speed to maintain the face velocity needed to capture fumes at the source.

-

Gas Sensors: Sensors at the exhaust outlet detect if the carbon bed is “saturated.” This ensures that toxic gases are never accidentally recirculated back into the breathing zone.

-

Automatic Shut-off: In the event of an overheat or a detected spark, the system can automatically cut power and trigger a fire suppression sequence, providing a final layer of fail-safe protection.

6. Conclusion: A Comprehensive Vision for Industrial Safety

An effective exhaust fume extraction system is much more than a vacuum cleaner; it is an integrated safety platform. By combining multi-stage mechanical filtration with chemical adsorption and explosion-proof structural engineering, manufacturers can create a “Triple Defense” that protects their most valuable assets: their employees and their equipment.

In the high-stakes environment of metalworking and laser processing, cutting corners on air quality is a gamble with human life and structural safety. By deploying a system that targets particulates, toxins, and explosions simultaneously, you transform your workshop from a hazardous zone into a center of sustainable, high-performance manufacturing. The air we breathe in the factory should be as clean as the products we create.