In the high-precision world of modern industrial manufacturing—where laser welding, 3D metal printing, and precision grinding are the norms—the greatest threat to air quality is often invisible. We are talking about sub-micron particles: ultra-fine metallic dust and fumes that are smaller than 1µm in diameter. These particles do not behave like…

In the high-stakes theater of microelectronics, semiconductor packaging, and precision sensor assembly, the margins for error have migrated from the visible to the sub-atomic. As components shrink to the micron level, the hazards they face have become equally invisible. Among these, Electrostatic Discharge (ESD) stands as a silent destroyer—an atmospheric…

PURE-AIR Professional Manufacturing Partner Introduction In today’s competitive industrial equipment market, reliable OEM and ODM manufacturing partners play a critical role in brand growth and product differentiation. As a professional industrial fume extractor manufacturer with over 14 years of R&D and production experience, PURE-AIR provides full-service OEM and ODM solutions…

Assembly & Quality Control in PURE-AIR Factory How We Ensure Industrial-Grade Reliability Introduction Consistent performance in industrial fume extraction systems depends not only on advanced design, but also on strict manufacturing standards and quality control procedures. At PURE-AIR, every industrial fume extractor is assembled and tested under standardized production protocols.…

How to Choose the Right Industrial Fume Extractor A Professional Buying Guide by PURE-AIR Introduction Selecting the right industrial fume extractor is a critical decision that directly impacts workplace safety, air quality compliance, production efficiency, and long-term operating costs. Many buyers focus only on airflow volume or equipment price, but…

Introduction Industrial production environments vary significantly in terms of process type, pollutant characteristics, airflow demand, and installation conditions. Standardized fume extraction equipment often fails to meet specific operational requirements. PURE-AIR provides customized industrial fume extraction solutions designed to match each customer’s production process, emission characteristics, and workspace layout. With over…

In vast, high-ceilinged workshops, monumental projects take shape. Here, a silent battle unfolds, driving creativity and precision. Public monuments, theatrical backdrops, and avant-garde installations emerge through relentless effort. It is the struggle between the boundless imagination of the creator and the physical reality of the medium. Whether carving stone, grinding…

For decades, the industrial spray painting environment has been defined by a singular, overwhelming sensory experience: the roar. The traditional image of a painting facility involves workers shouting to be heard over the relentless thrum of high-powered fans and the turbulent rush of air. In this high-decibel “roaring workshop,” noise…

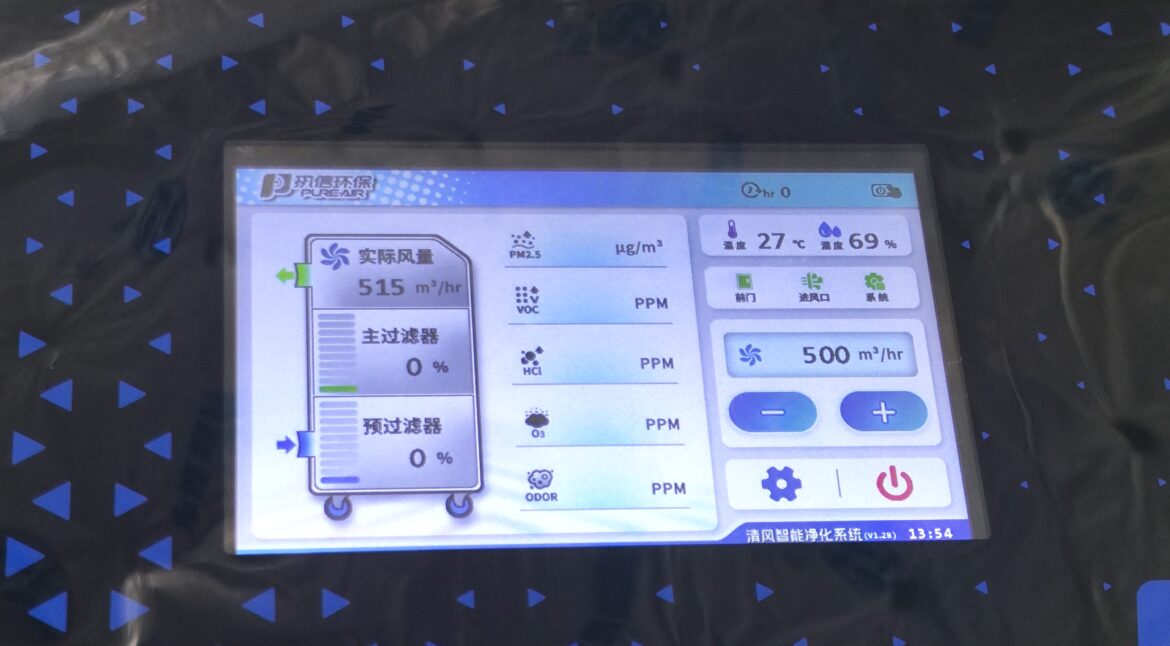

Introduction As industrial production becomes increasingly automated and performance-driven, traditional passive filtration systems can no longer fully meet modern air quality control requirements. PURE-AIR developed the PIPS Intelligent Purification System (PIPS) to combine hardware filtration with real-time monitoring, smart control logic, and performance optimization. PIPS is not simply a controller…

High Negative Pressure Fan vs Standard Fan Understanding the Key Difference in Industrial Fume Extraction Performance Introduction The fan system is the core power source of any industrial fume extraction system. While many purification devices use standard ventilation fans, industrial-grade fume extractors require high negative pressure fans to ensure stable…