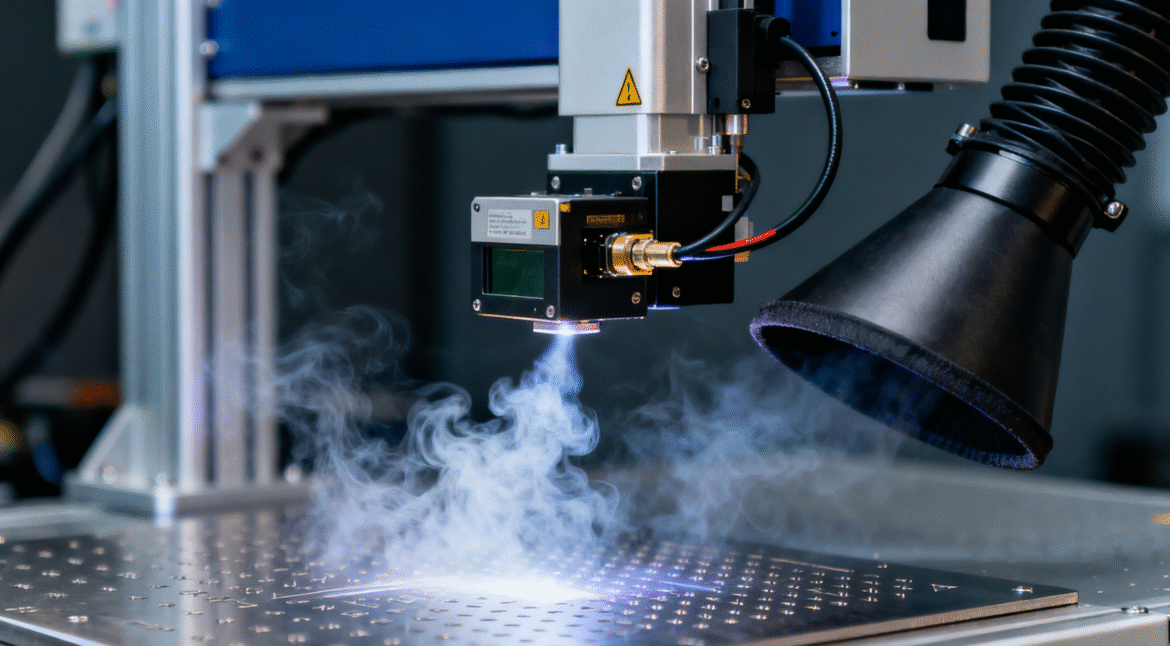

Industrial Fume Extractor Manufacturer with 14 Years of Expertise | PURE-AIR Professional Industrial Fume Extraction Solutions for Modern Manufacturing With the rapid development of modern manufacturing, industrial processes such as laser cutting, laser marking, laser engraving, welding, soldering, and electronic production generate large amounts of smoke, dust, and hazardous airborne…

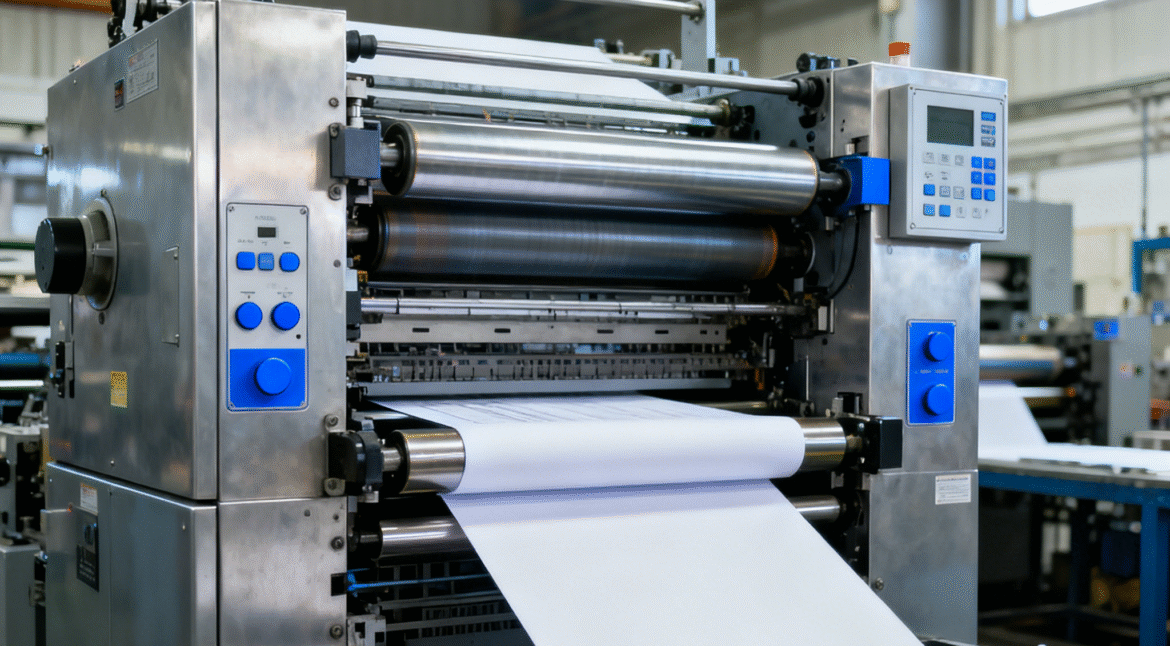

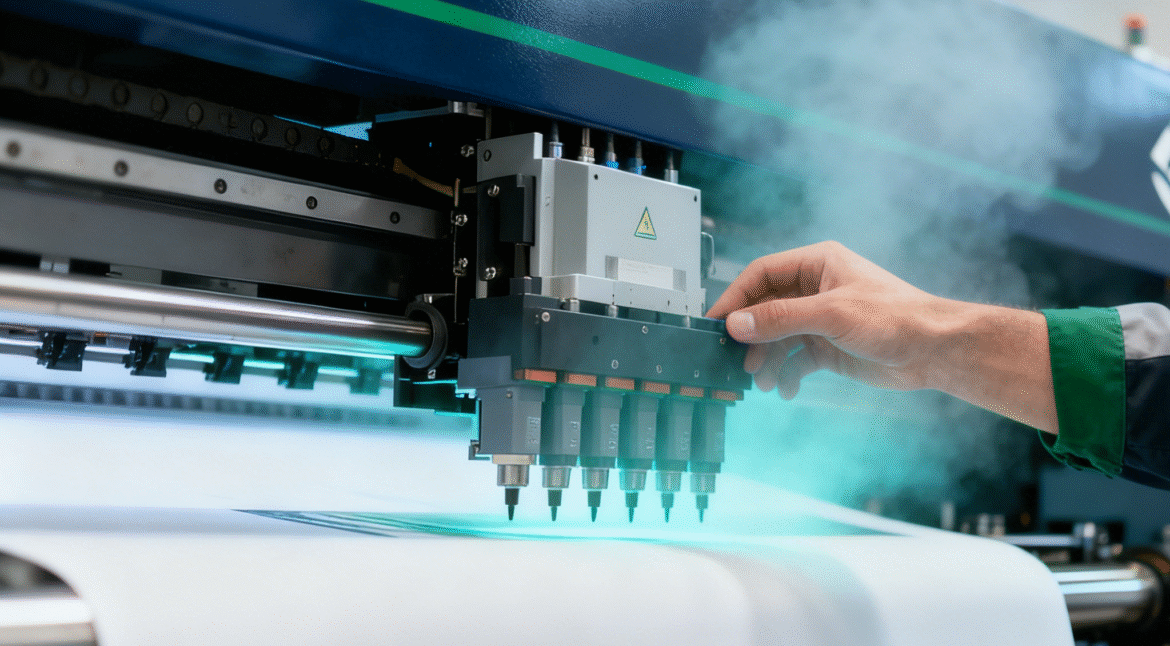

In printing workshops, people often talk about that familiar “smell,” originating from inks, varnishes, adhesives, and solvents. Many believe that eliminating these odors equates to removing all health risks. However, a deep dive into safety data sheets reveals a far more complex reality—many emissions of concern are invisible and may…

In industrial ventilation, “99% capture efficiency” often appears as a reassuring number. On paper, it suggests that harmful fumes, particles, and gases remain under control. However, in real robotic welding environments, this figure is rarely the end of the story. In fact, it is often only the starting point. Robotic…

In heavy industries such as shipbuilding and construction machinery manufacturing, welding remains one of the most essential yet challenging processes. Large structural components, complex welding positions, long weld seams, and continuous high-current operations generate massive amounts of welding fumes. These fumes are not only dense and persistent but also highly…

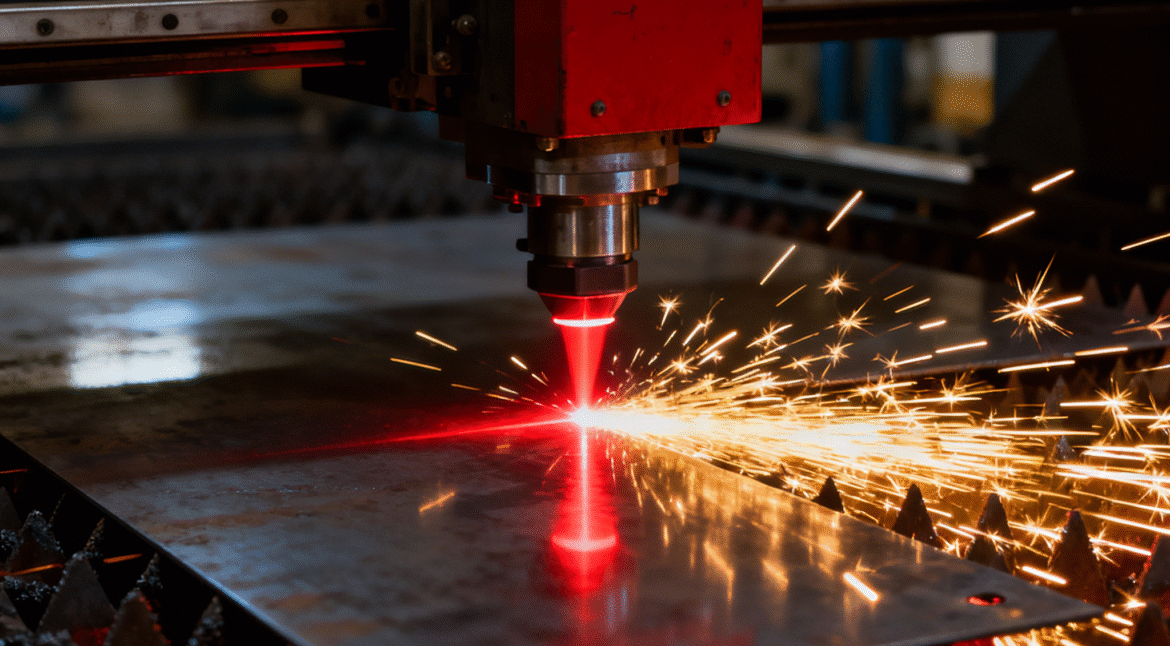

In the pulse of modern industrial production, processes such as welding, laser cutting, and grinding create value while also generating visible and invisible byproducts—industrial fumes and hazardous gaseous pollutants. These fine particulate matters, often smaller than 20 microns in diameter, escape the naked eye yet can travel deep into the…

In the field of industrial fume purification, equipment managers have long been troubled by two core questions: “Is the suction power consistently effective?” and “When exactly should the filter be replaced?” Traditional practices rely on empirical judgment or fixed replacement schedules—often resulting in either compromised safety due to performance degradation…

Air quality impacts productivity, safety, and compliance across all manufacturing sectors. Therefore, factories continue to invest heavily in high-efficiency fume purifier solutions that capture harmful particles at the source. As manufacturing complexity grows, many buyers must choose between electrostatic fume purifiers and HEPA filtration systems. Although both technologies remove airborne…

In printing workshops, that distinctive “smell”—a blend of inks, varnishes, and solvents—has long been accepted as the industry’s background noise. This odor is fundamentally a mixture of fumes and VOCs (Volatile Organic Compounds) released during various printing processes like offset, digital, screen printing, and UV curing. However, the core issue extends far…

In traditional production management, industrial fumes are often seen as an unavoidable byproduct. However, from the perspective of modern intelligent manufacturing, untreated workshop fumes are quietly consuming a company’s core profits. Today, let’s analyze how a professional industrial fume purifier transforms from a “cost expenditure” into a “value investment,” safeguarding…

Why They Are Becoming a Global Manufacturing Essential As global manufacturing continues to evolve and environmental regulations become stricter, fume extractors are rapidly shifting from an optional accessory to a mandatory standard across multiple industries.From laser processing to electronic soldering, from new-energy manufacturing to laboratory applications, industrial air purification systems…