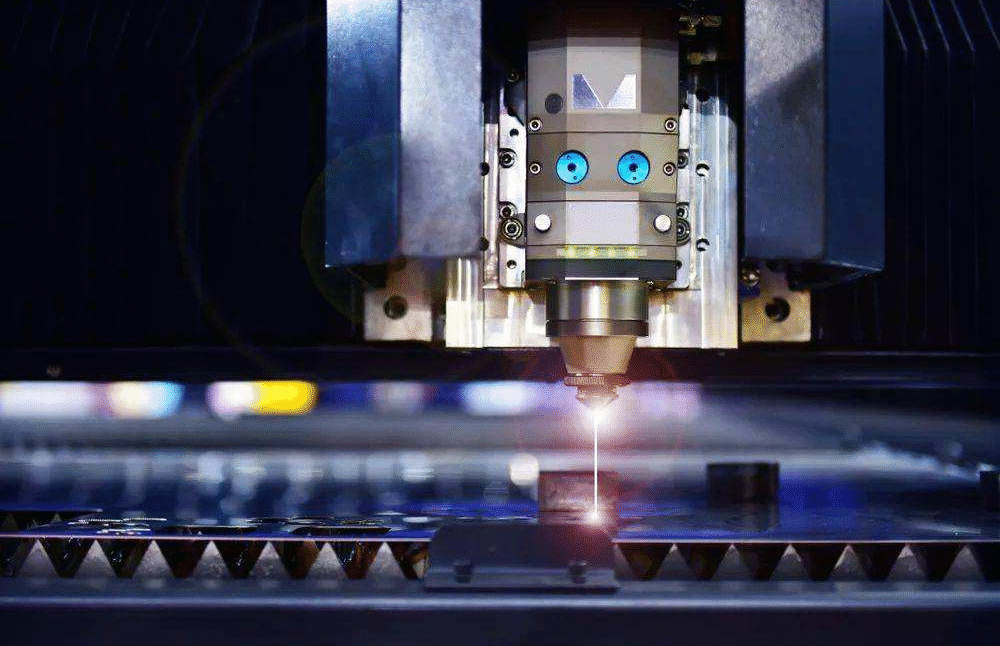

Laser cleaning has rapidly become one of the fastest-growing surface-treatment technologies in modern manufacturing. With advantages such as precision removal, zero consumables, and environmentally friendly operation, it is now widely used in aerospace, automotive manufacturing, mold repair, cultural relics restoration, and metal processing. However, while laser cleaning eliminates chemical solvents…

In automotive manufacturing and repair shops, welding is an essential process. However, welding also generates hazardous fumes that can pose significant risks to workers’ health. Efficient welding fume extraction is not just a regulatory requirement; it’s a vital step in maintaining a safe working environment and ensuring the longevity of…

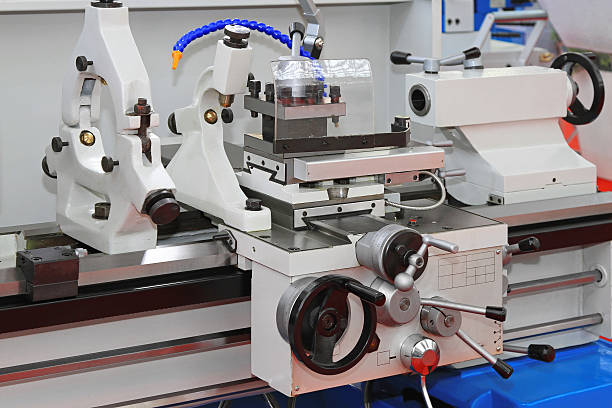

In modern machining environments, precision and efficiency define competitiveness. However, many factories overlook a silent and persistent threat that directly affects productivity: particulate contamination. During turning, milling, grinding, and drilling, airborne dust and chips accumulate around cutting tools. These particles accelerate wear, destabilize cutting edges, and introduce thermal stress. As…

In modern industrial manufacturing, laser marking has become a core technology for product traceability, anti-counterfeiting, and brand identification. Whether it’s electronic components, metal parts, automotive accessories, or plastic packaging, laser marking is widely used due to its advantages of high precision, high speed, and permanent marking. However, while many companies…

In today’s advanced manufacturing industry, laser marking has become one of the most widely used processes for product identification and traceability. From electronics and automotive parts to medical devices and metal tools, laser marking ensures precision, durability, and high production efficiency. However, behind every clean and precise mark lies a…

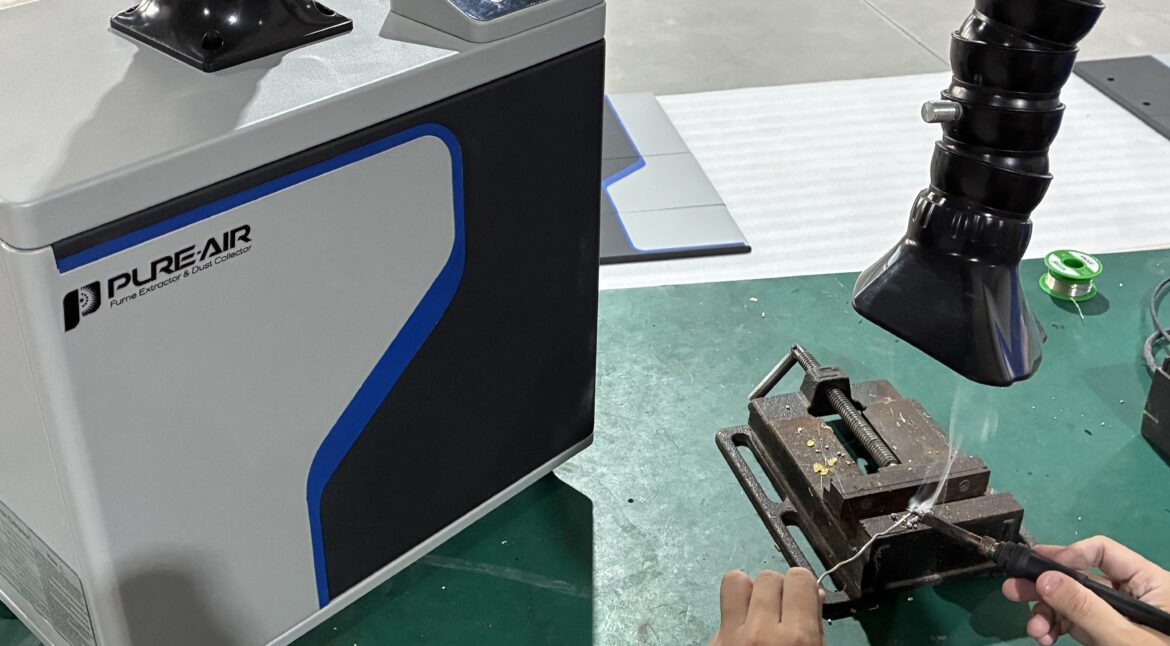

In modern manufacturing environments, processes like laser marking and electronics soldering have become essential to ensure precision, efficiency, and innovation. However, both processes generate harmful fumes, particulates, and chemical residues that can threaten operator health, product quality, and equipment longevity. At PURE-AIR, we provide advanced industrial fume extraction systems specifically…

Today, PURE-AIR was honored to welcome our strategic partner from Russia — the ASRUS X team — to our headquarters for a full-day technical exchange and cooperation meeting. This visit marks another solid step forward in our global market expansion and deep collaboration in industrial fume purification technologies. A Warm…

In the constantly evolving landscape of modern manufacturing, speed and precision are often seen as the ultimate goals. Yet, behind the hum of machines and the rhythm of production lines lies an often-overlooked factor that quietly shapes long-term performance—air quality. As Black Friday draws near, companies are not just searching…

In today’s rapidly advancing manufacturing world, clean air is not a luxury—it’s a necessity. As factories move toward greater precision and environmental responsibility, the industrial dust collection system has evolved from a supporting tool into the beating heart of production efficiency and workplace safety. These systems no longer serve as…

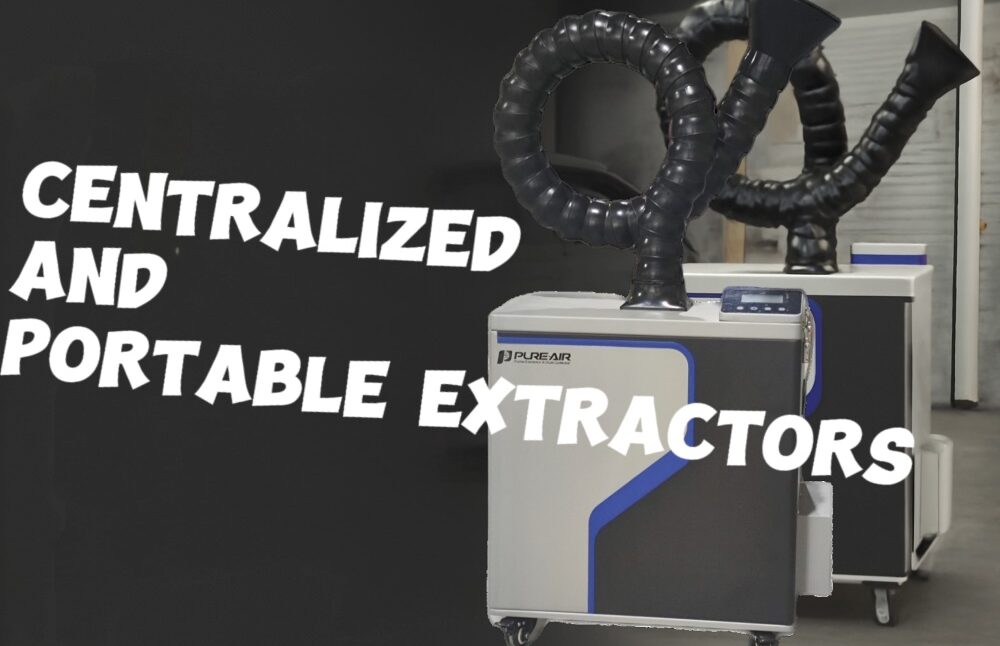

For years, many companies have relied on vent-to-air or centralized exhaust systems for their fume extraction needs. However, with the rise of agile manufacturing practices, portable extraction systems, like those designed by PURE-AIR, have become an increasingly popular choice among businesses looking for flexibility and performance. While centralized systems remain…