Why Factories Need Laser Fume Extraction Systems Protecting Health, Equipment, and Compliance in Modern Manufacturing In today’s advanced manufacturing environment, laser technology is widely used in cutting, marking, welding, and engraving. While lasers bring higher precision and efficiency, the smoke and ultrafine dust released during processing can create silent but…

In industrial factories, the terms fumes and vapors might seem interchangeable — but in reality, mistaking one for the other can lead to the wrong safety measures, ineffective filtration, and increased health risks. At PURE-AIR, we believe understanding this difference is key to designing effective air-purification solutions for laser cutting,…

Poor design or under-investment in the dust collection and extraction system can translate into significant hidden costs—reduced equipment lifespan, compromised process accuracy, increased downtime, and higher maintenance bills. In this article, we analyse how improper dust extraction in laser cutting environments affects operations at multiple levels and guide industrial dust…

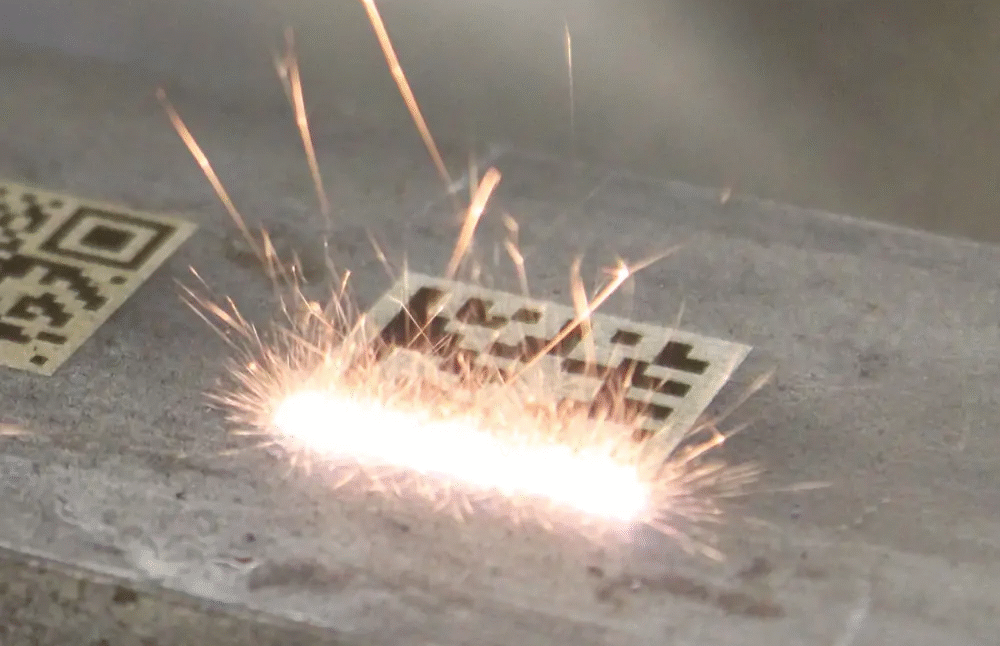

The Growing Importance of Dust Control in Laser Cutting In the modern industrial landscape, laser cutting has become an essential process across automotive, metal fabrication, and electronics manufacturing. Its precision and speed are unmatched. However, as laser cutting efficiency increases, so does the generation of fine dust and smoke. These…

In the era of high-precision manufacturing, many industrial procurement teams focus on machine speed, accuracy, and automation. However, behind those laser beams lies a lesser-seen threat: fine dust and fumes generated during the cutting process. Understanding the hidden risk of laser cutting dust is essential. With this article, we at…

PURE-AIR Industrial Dust Purification System: 14 Years of Ingenious Research and Development, Reshaping the Standard for Industrial Air Purification with Core Technology —Leading the Global Clean Production Revolution with Innovative Technology and Superior Quality In modern industrial production environments, smoke, dust, and harmful gases generated by processes like welding, laser…

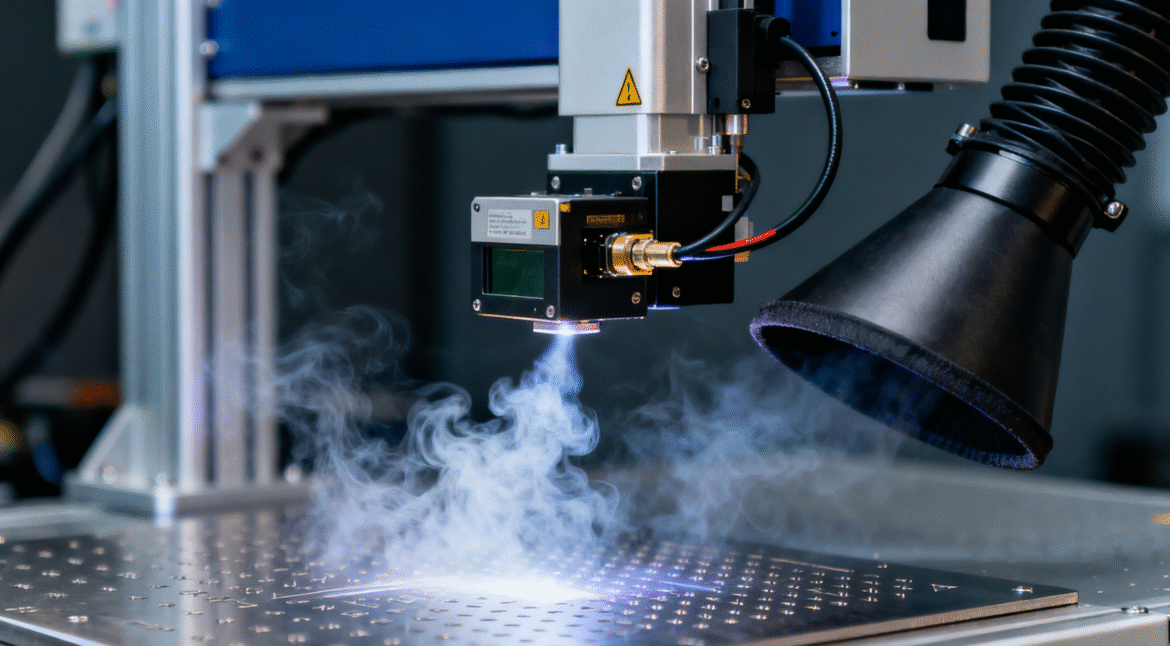

Why Air Filtration Efficiency Matters in Modern Laser Cutting Factories In modern manufacturing, laser cutting technology has become essential for industries that demand precision and productivity. From automotive parts to metal fabrication and electronics, laser cutting delivers speed and accuracy. However, behind the precision lies a growing environmental and health…

In the field of laser manufacturing, precision is everything. From semiconductor fabrication to laser engraving and medical device production, even microscopic dust or vapor particles can compromise optical clarity and accuracy. Maintaining a clean and stable working environment is, therefore, not an option but a necessity. This is where an…

In today’s industrial environment, factories and plants face increasing demands to control airborne contaminants, volatile organic compounds (VOCs), and odorous gases. For procurement teams, plant managers, and equipment buyers, understanding the science behind a reliable solution matters. This article focuses on activated carbon filters in the context of industrial fume…

In modern industrial production systems, manufacturing processes such as welding, laser cutting, and grinding generate industrial fumes and dust that have become critical factors affecting sustainable business development. These complex pollutants, composed of metal oxides, toxic gases, and suspended particulate matter, not only directly threaten employee health but also damage…