Fume Extraction Solutions for Welding Workshops

Introduction: Why Welding Fume Control Is Critical

Welding workshops generate large volumes of hazardous fumes containing metal oxides, fine particulates, ozone, nitrogen oxides, and volatile organic compounds (VOCs). Without effective fume extraction, these pollutants accumulate rapidly in enclosed production areas, leading to serious health risks, regulatory non-compliance, and reduced operational efficiency.

At PURE-AIR, with over 14 years of industrial air purification R&D and manufacturing experience, we provide high-performance welding fume extraction solutions designed to deliver stable airflow, high negative pressure capture, and long-term filtration reliability for professional welding environments.

Common Air Quality Challenges in Welding Workshops

1. High Concentration of Fine Particles

Welding fumes typically contain ultra-fine particles smaller than 1 micron. These particles remain airborne for extended periods and can easily penetrate deep into the lungs.

2. Heavy Metal Contamination

Processes such as MIG, TIG, laser welding, and arc welding generate hazardous substances including:

-

Manganese

-

Chromium

-

Nickel

-

Aluminum oxide

Long-term exposure may cause respiratory disease, neurological damage, and occupational illness.

3. Inconsistent Airflow in Traditional Ventilation

General ventilation systems often fail to capture fumes directly at the source, allowing contaminants to spread throughout the workshop.

PURE-AIR Welding Fume Extraction Solution Architecture

PURE-AIR systems are designed based on source capture + high negative pressure airflow + multi-stage filtration principles.

Core System Structure:

-

High Negative Pressure Industrial Fan

-

PIPS Intelligent Purification System

-

Multi-Layer Long-Life Filter Cartridge

-

Spark Protection & Pre-Filter Module

-

Intelligent Control Panel

This architecture ensures stable suction performance even during continuous welding operations.

High Negative Pressure: Key to Effective Welding Fume Capture

Unlike standard ventilation fans, PURE-AIR systems use high negative pressure centrifugal fans that:

-

Capture fumes directly at the welding source

-

Prevent fume diffusion across work areas

-

Maintain stable airflow over long duct distances

-

Support multi-station extraction networks

This design is essential for workshops with multiple welding bays or robotic welding cells.

Multi-Stage Filtration System for Welding Applications

PURE-AIR welding fume extractors apply a multi-stage purification process:

Stage 1 – Spark Arrest & Pre-Filtration

-

Captures large particles and sparks

-

Protects downstream filter layers

-

Extends filter lifespan

Stage 2 – High-Efficiency Fine Particle Filtration

-

HEPA-grade filtration optional

-

Removes submicron metal particles

-

Efficiency up to 99.97%

Stage 3 – Activated Carbon Module (Optional)

-

Removes odors and VOCs

-

Suitable for stainless steel welding and coated materials

Customized Solutions for Different Welding Environments

PURE-AIR offers customized configurations based on workshop layout and production requirements:

Single Station Welding

-

Portable fume extractors

-

Flexible extraction arms

-

Compact footprint

Multi-Station Welding Lines

-

Centralized extraction systems

-

Duct network integration

-

Automatic airflow balancing

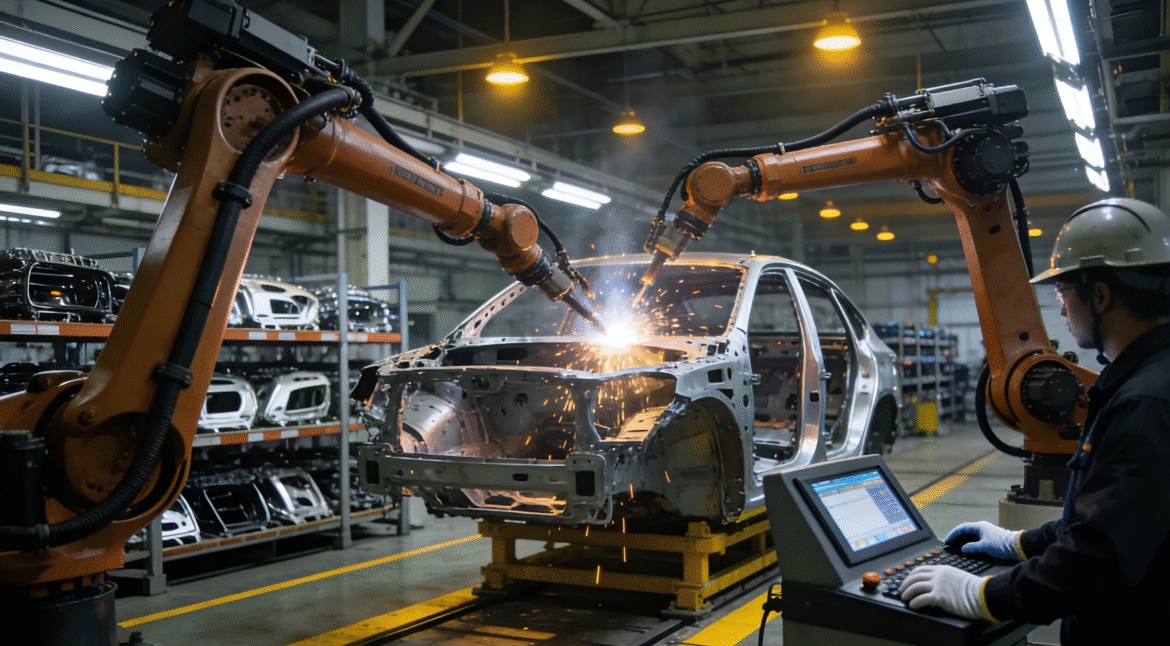

Robotic Welding Cells

-

Enclosed extraction hoods

-

High airflow stability

-

Automated system integration

Benefits of PURE-AIR Welding Fume Extraction Systems

Improved Worker Health & Safety

-

Reduced respiratory exposure

-

Cleaner breathing environment

-

Compliance with occupational safety standards

Enhanced Production Efficiency

-

Better visibility during welding

-

Reduced equipment contamination

-

Lower maintenance downtime

Regulatory Compliance Support

PURE-AIR systems help workshops comply with:

-

OSHA welding fume exposure limits

-

Local environmental regulations

-

Factory audit requirements

Why Choose PURE-AIR for Welding Fume Extraction?

With over 14 years of manufacturing experience, PURE-AIR provides:

-

In-house developed high negative pressure fans

-

Proprietary PIPS intelligent purification system

-

Long-life industrial filter technology

-

OEM & ODM customization capability

-

Stable global supply support

Our factory focuses on core component assembly, electronic control integration, and system quality testing, ensuring consistent performance and long-term reliability.

Conclusion

Effective welding fume extraction is not optional — it is a critical investment in worker safety, production stability, and environmental compliance. PURE-AIR delivers professional-grade solutions designed for demanding industrial welding environments.

Whether you operate a small fabrication workshop or a large automated welding production line, PURE-AIR can provide a tailored solution to meet your exact needs.