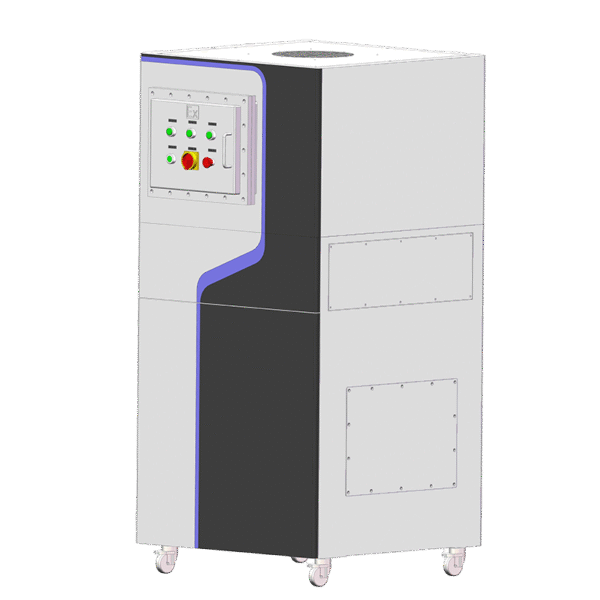

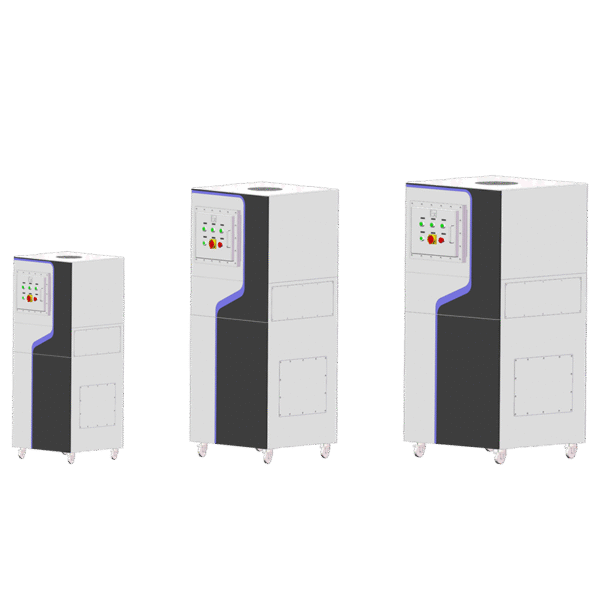

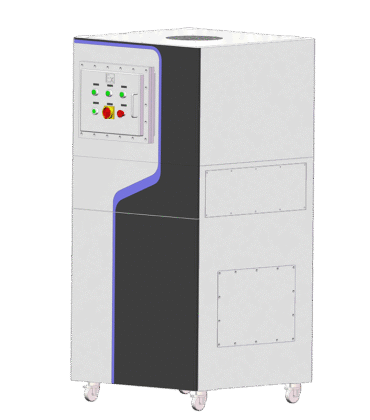

High-Efficiency Laser Cladding Fume Extractor

The PURE-AIR D-i Series laser cladding fume extractor sets a new benchmark for industrial dust purification. Designed for aerospace, high-speed rail, and wind energy sectors, it delivers powerful performance with advanced negative pressure technology and a composite filter system. Businesses achieve efficient and compliant dust control with this flagship solution.