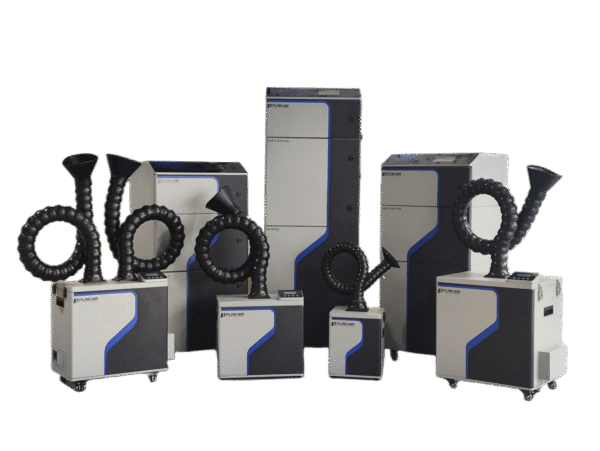

[PURE-AIR]——Redefine the limit of precision manufacturing purification!

Specializes in ultra-clean processing of photovoltaic panels/PCB/ceramics!

Photovoltaic precision smoke and dust purification flagship|Zero space invasion + quantum pulse|[PURE-AIR]

![Overall design: [Smart Manufacturing, Space Revolution] --- Subvert tradition and reduce space occupancy by 40%!](https://www.pureairen.com/wp-content/uploads/2025/05/生成智能净化图片-4.jpg)