Industrial Fume Control for Welding Operations.

PURE-AIR eliminates toxic hexavalent chromium, manganese fumes, and zinc oxides generated during MIG/TIG/stick welding – protecting operator health and reducing equipment corrosion risks.

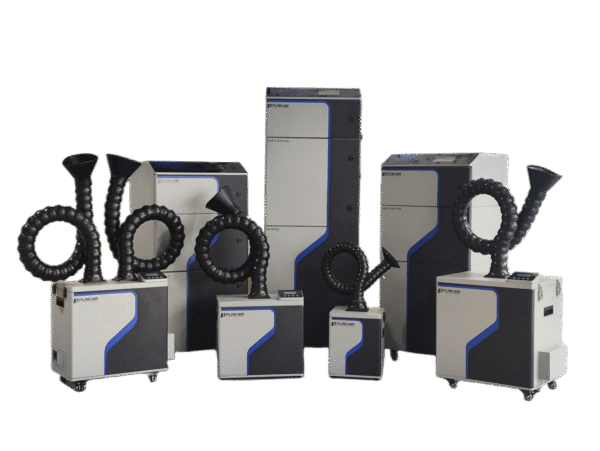

D Series (Welding Fume Extractor)

x