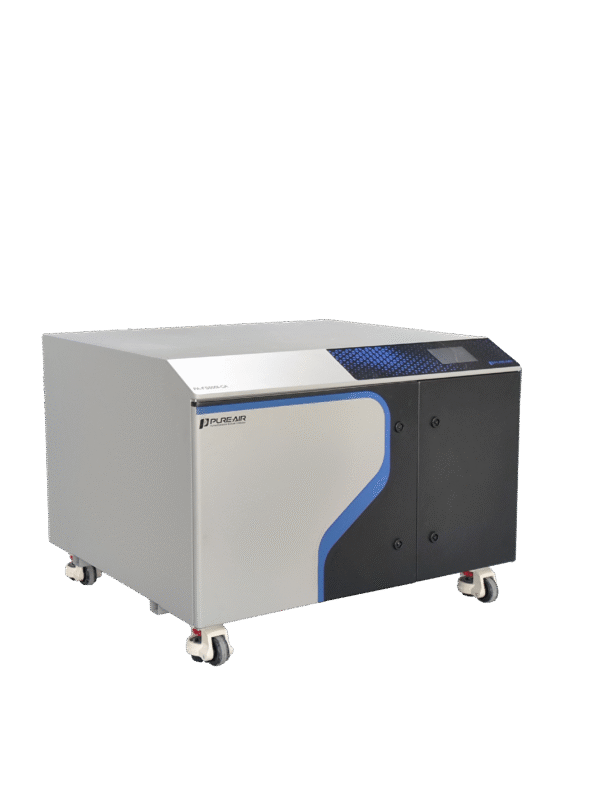

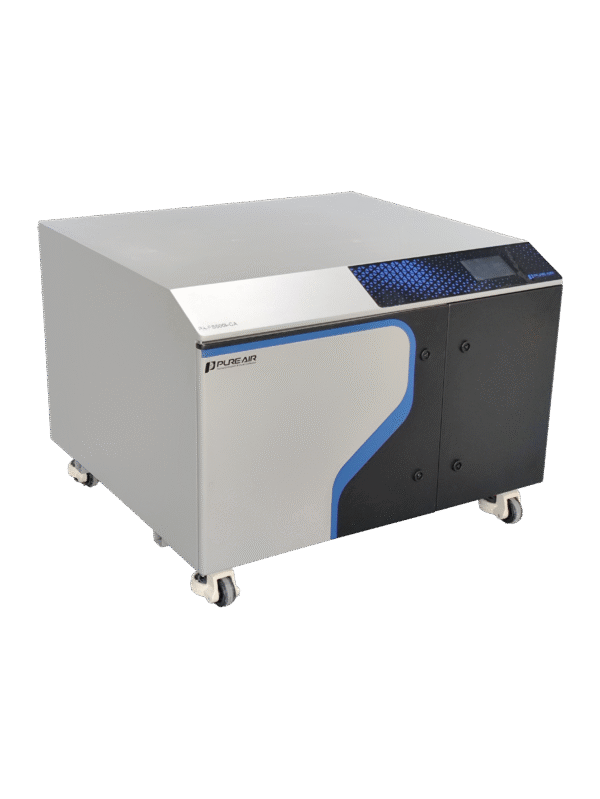

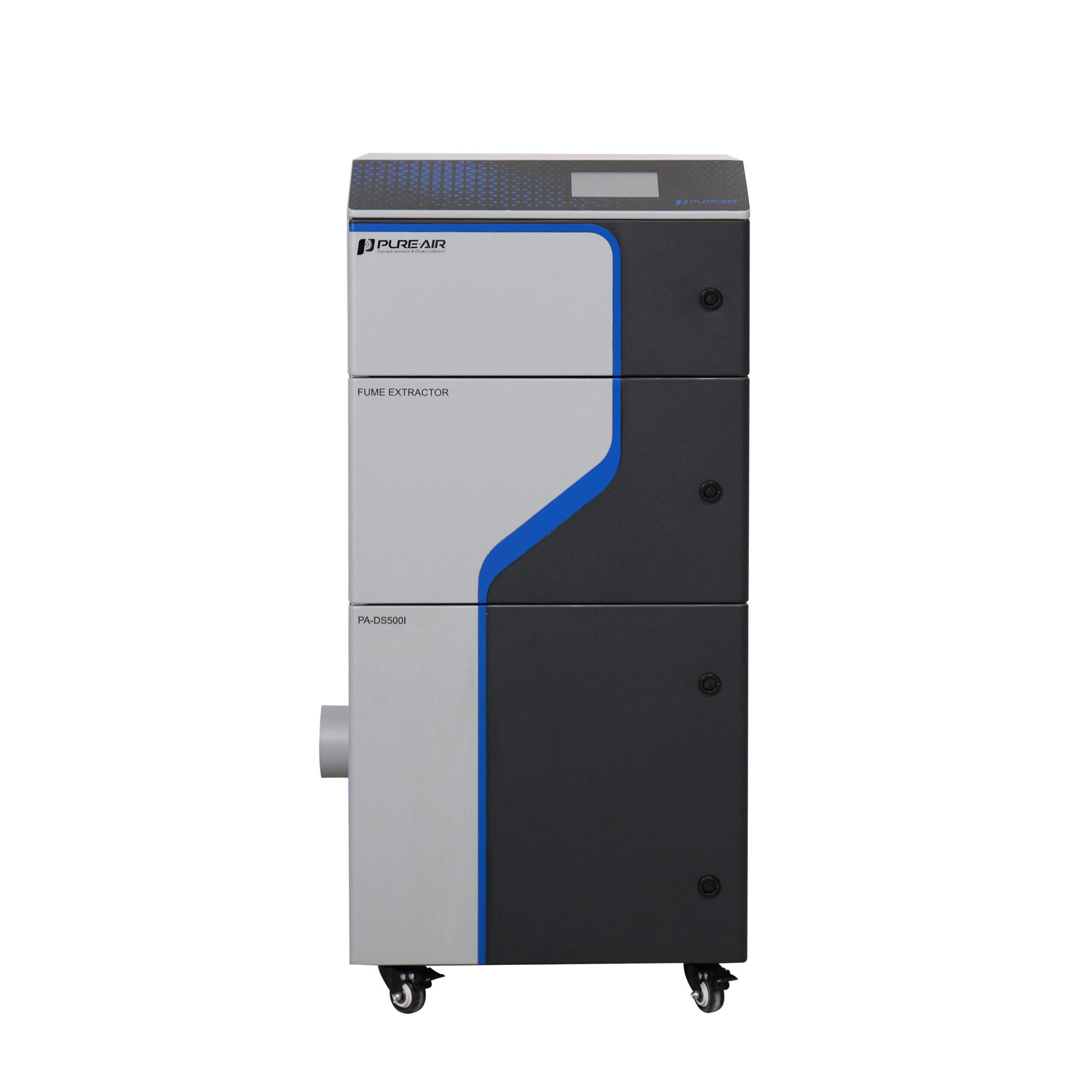

DFS-i Series Carbon Fiber Smoke Fume Extractor for Gluing and Potting

PURE-AIR DFS-i carbon fiber smoke fume extractor offers 99.99% nano-level purification and military-grade sealing. It ensures clean air for composite and aerospace applications. Contact us today to customize your solution and enhance workplace safety.