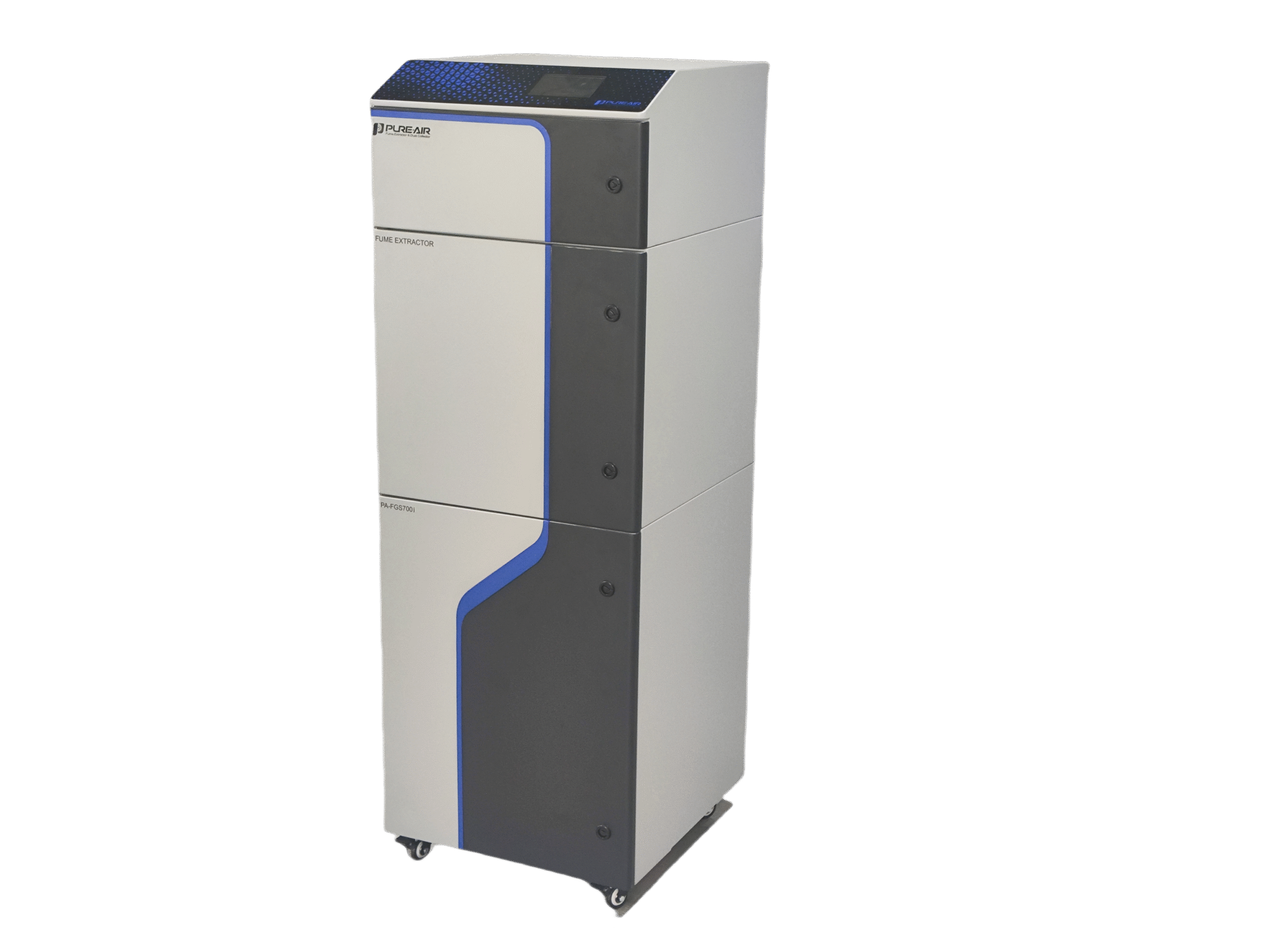

DFS-i Series Conformal Coating Fume Extractor

The PURE-AIR DFS-i Series is designed to purify harmful fumes from carbon fiber and aerospace composites, providing 99.99% filtration efficiency. Ideal for industrial environments, this fume extractor is perfect for businesses looking to ensure a clean and safe working space. Contact us now for bulk orders and advanced fume extraction solutions.