High-Value Laser Cleaning Fume Extraction

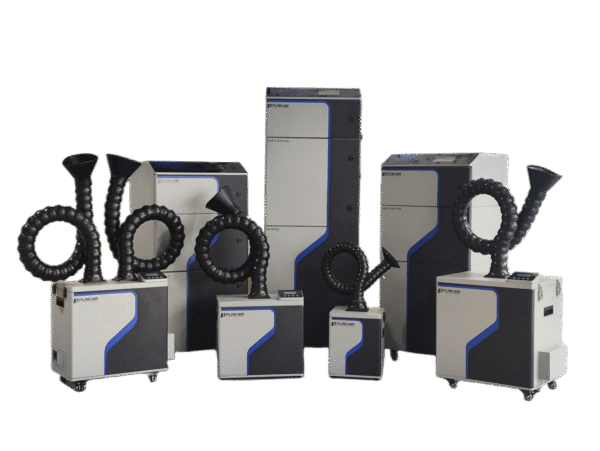

The DFS Series uses advanced laser cleaning technology. It removes oxide layers, rust, and surface impurities efficiently and safely. The device ensures air purification at museum-level standards, making it perfect for cultural relics and industrial applications.