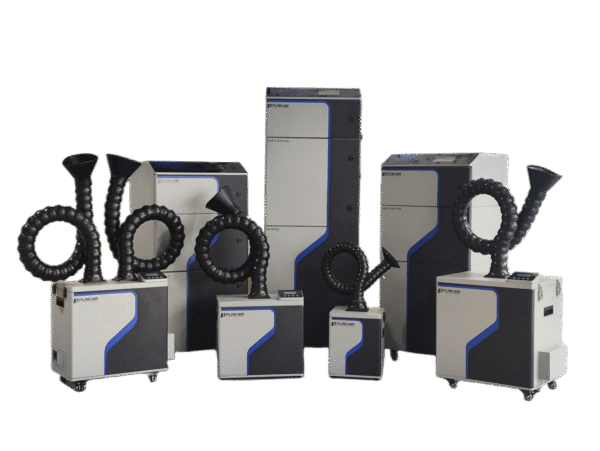

PURE-AIR DS-i Series Fume Extractor for PCB Assembly & Manufacturing

PURE-AIR DS-i Series efficiently removes toxic solder fumes and particulates. It ensures safe PCB assembly and production. Ideal for electronics manufacturers, this system combines compact design, intelligent monitoring, and high-efficiency purification. Welcome to order in bulk for your production line and enhance workplace safety today!