PURE-AIR F Series Soldering Fume Extractor

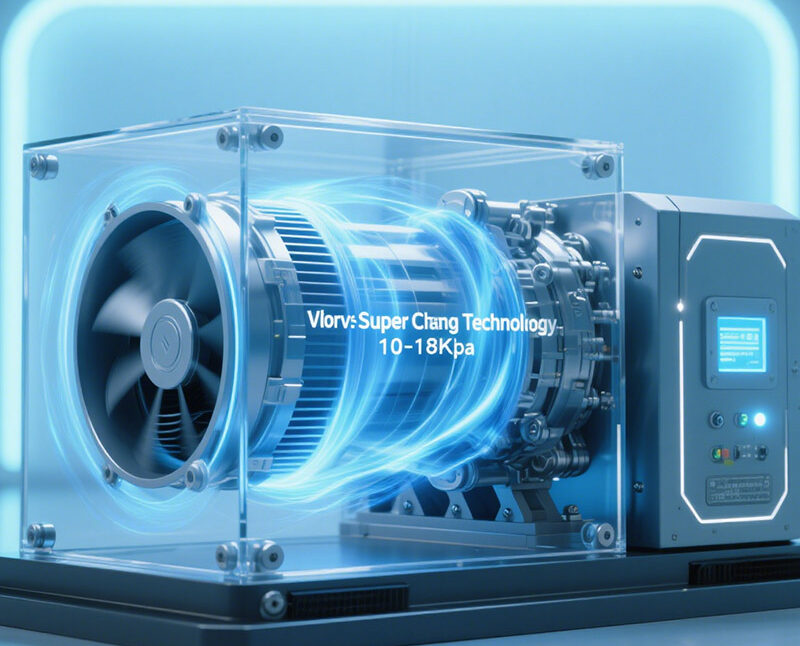

The PURE-AIR F Series soldering fume extractor provides targeted purification for soldering fumes and odors. It protects operators and sensitive equipment from toxic particulates and rosin fumes generated during manual or automated soldering processes. With high efficiency and stable performance, this extractor delivers industrial-grade air purification while maintaining workspace safety and compliance.