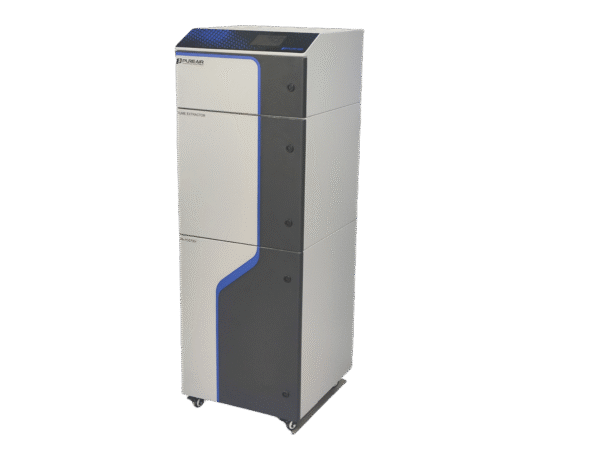

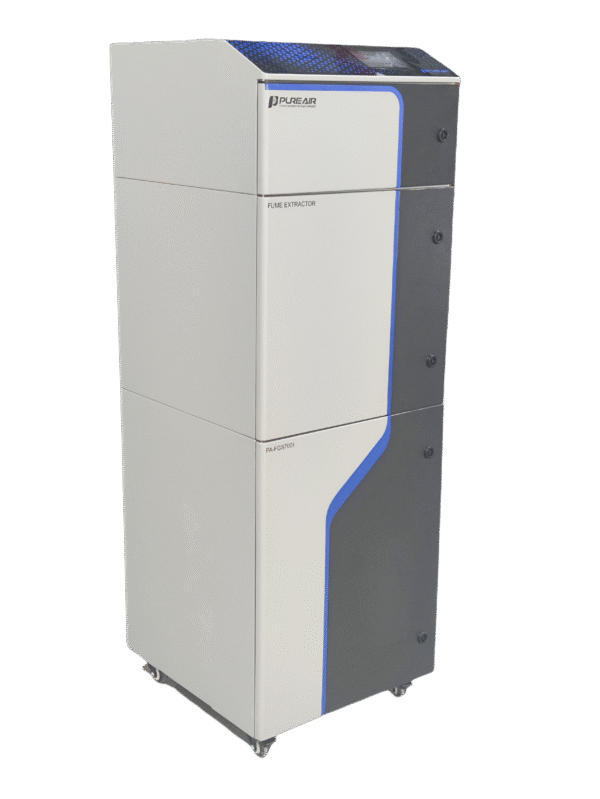

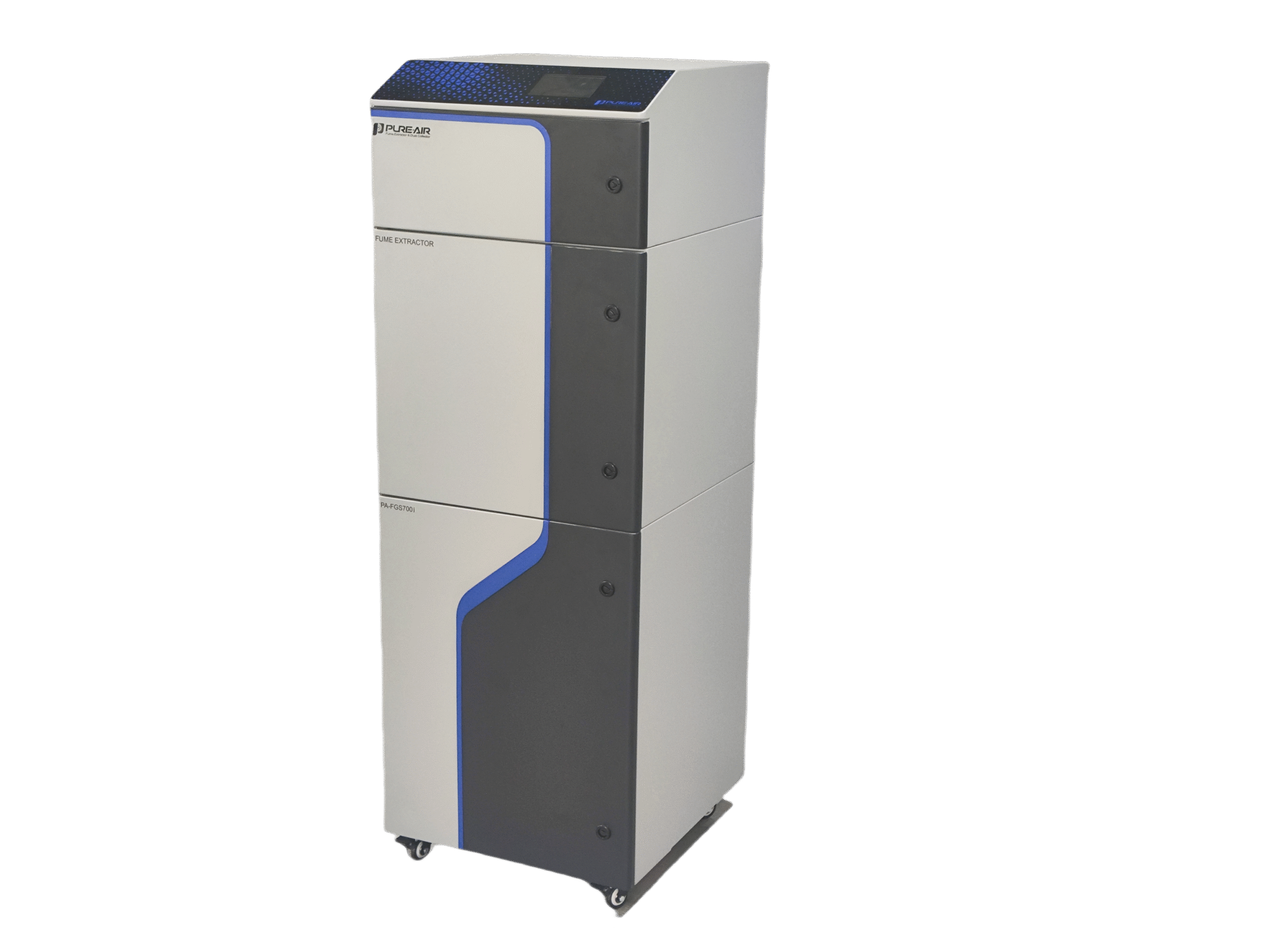

FGS-i Series Conformal Coating Fume Extractor Solutions

The FGS-i Series Conformal Coating Fume Extractor by PURE-AIR is engineered to tackle sticky smoke issues in the laser processing of wood, rubber, and two-color plates. With its PIPS purification system, this extractor achieves 99.9% particle filtration, saving 40% space while ensuring high performance. Perfect for industrial applications, it features a self-cleaning filter, making it a reliable and efficient solution for your business. Contact us today for bulk orders!