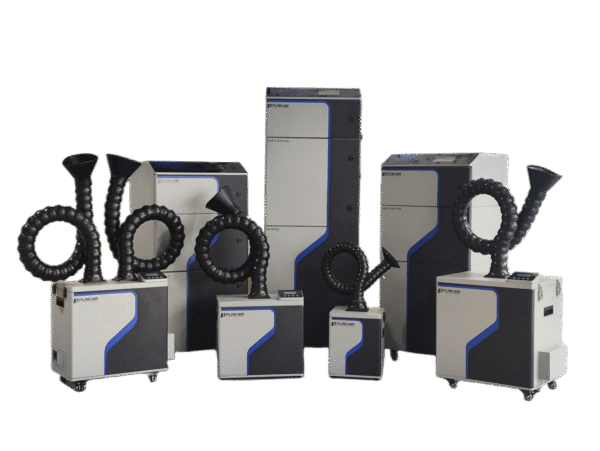

FS-i Series 3D Non-Metal Printing Fume Extractor

PURE-AIR FS-i Series non-metal printing fume extractor delivers professional purification for polymer 3D printing environments. We’re now seeking global distributors and dealers to expand our market network. Partner with PURE-AIR to promote a cleaner and safer future for industrial printing facilities.