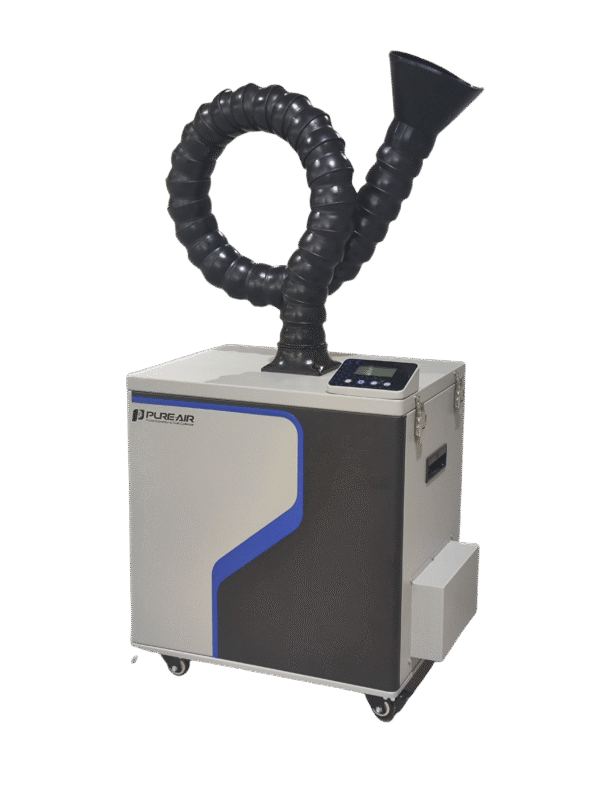

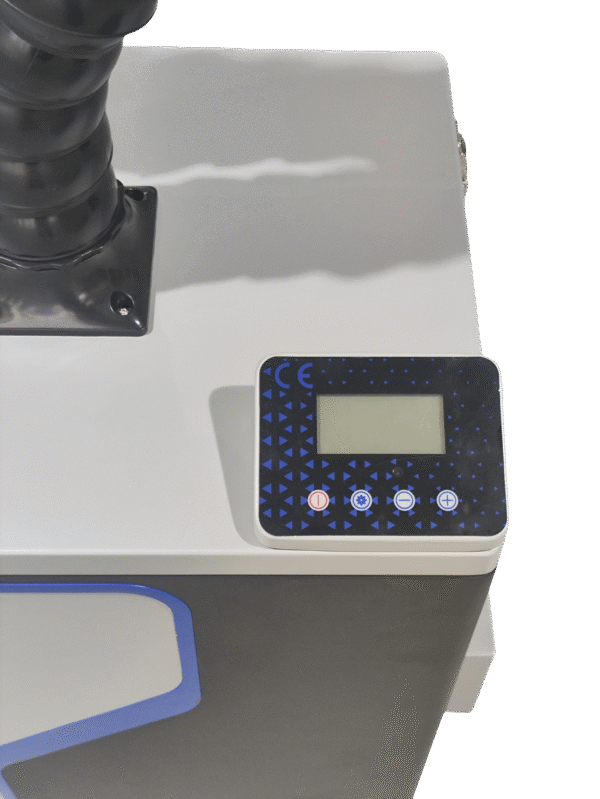

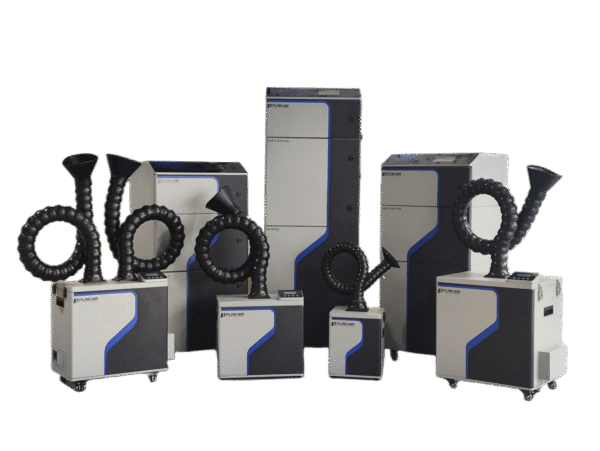

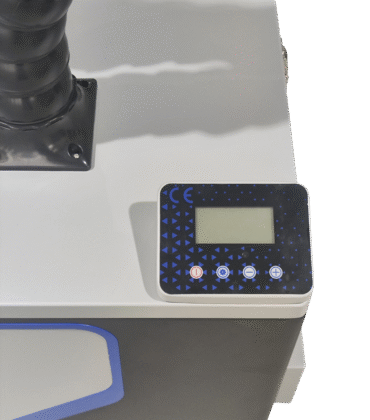

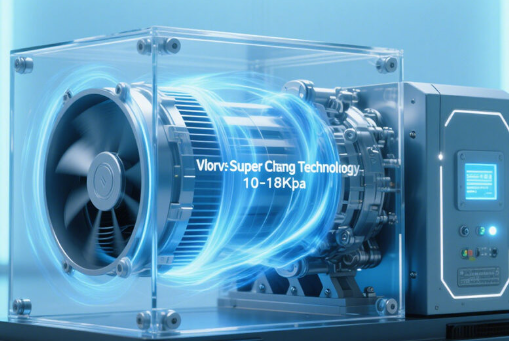

FS-i Series Inkjet and UV Printing Fume Extraction Unit

Looking for a high-performance fume extraction unit to keep your printing operations safe and efficient? The PURE-AIR FS-i Series Inkjet and UV Printing Fume Extraction Unit delivers cutting-edge purification technology designed for modern inkjet and UV curing environments.