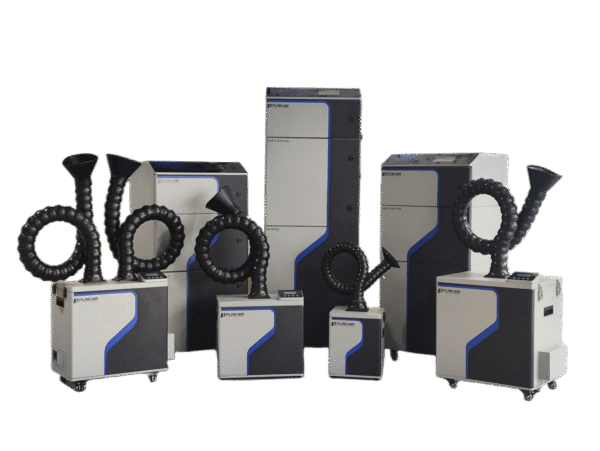

FS Series Fume Extractor for Sublimation Operations

PURE-AIR’s FS Series fume extractor for sublimation operations offers advanced filtration and energy-efficient purification. We are now seeking global distributors and agents to expand our market network. Join us to bring clean air technology to every sublimation workshop!