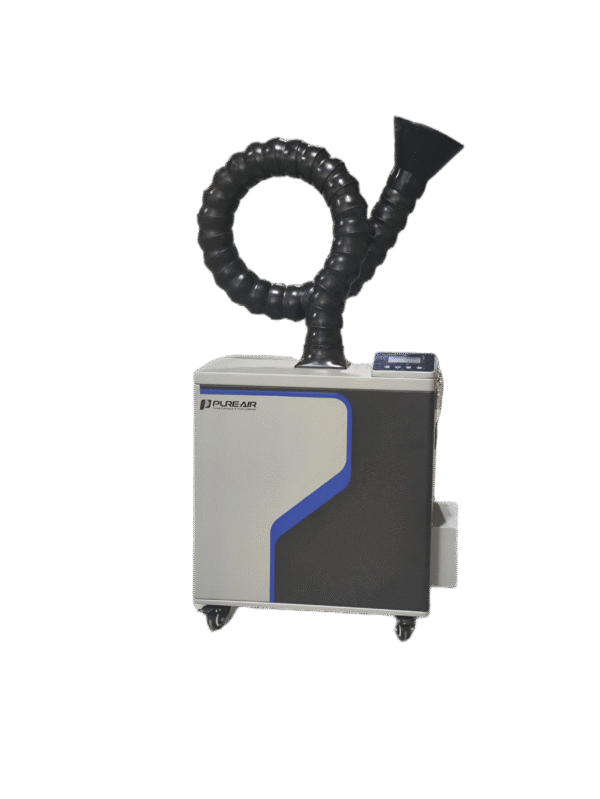

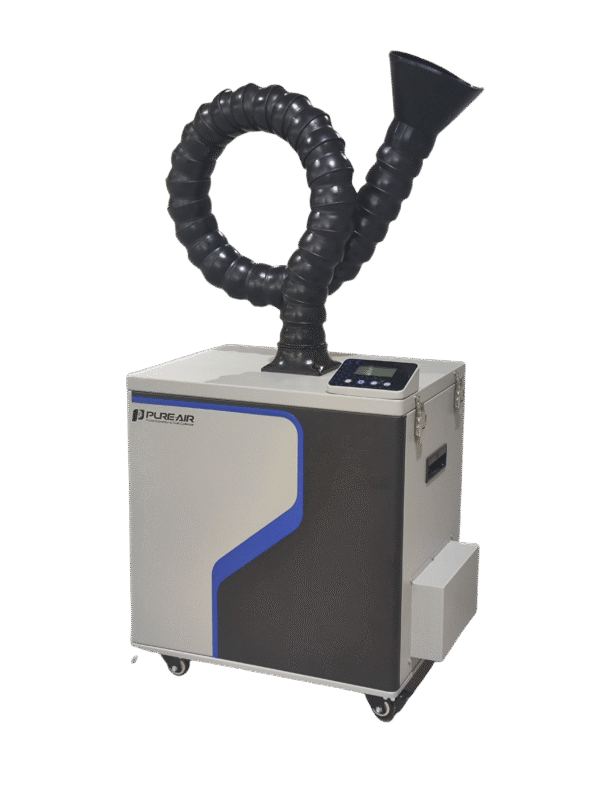

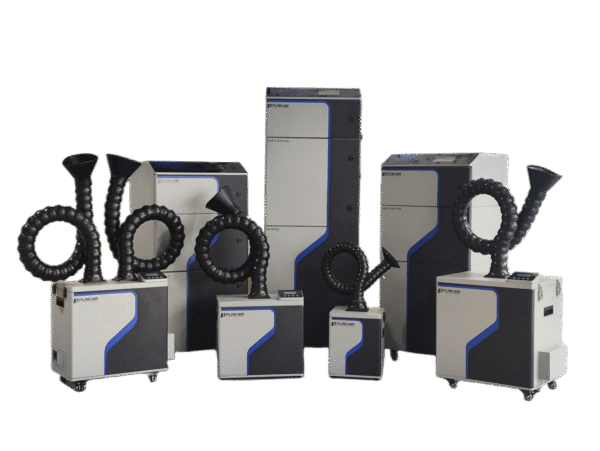

Efficient UV Printing Fume Extraction

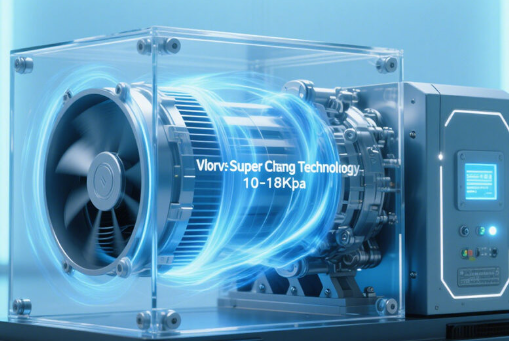

The PURE-AIR FS Series UV printing fume extractor removes toxic fumes, solvent vapors, and VOCs generated during inkjet and UV printing. It creates a safe and healthy working environment for operators and protects sensitive printing equipment from contamination.