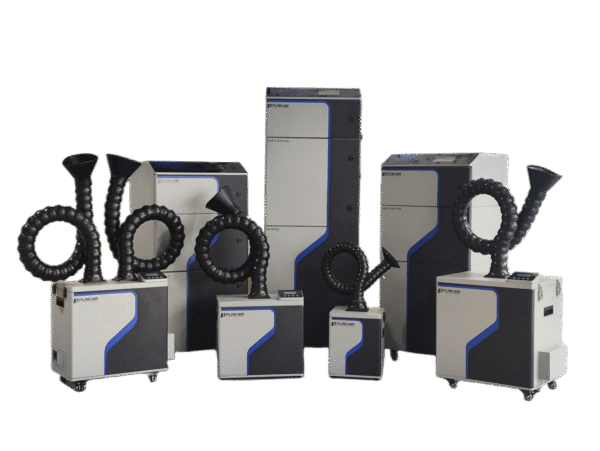

FS Series PCB Assembly & Manufacturing Welding Fume Purifier

Protect your workspace with the PURE-AIR FS Series Welding Fume Purifier. Designed for PCB assembly and manufacturing, it delivers powerful filtration performance and ensures operator safety. Contact us now for bulk orders to improve your production environment today!