Why They Are Becoming a Global Manufacturing Essential As global manufacturing continues to evolve and environmental regulations become stricter, fume extractors are rapidly shifting from an optional accessory to a mandatory standard across multiple industries.From laser processing to electronic soldering, from new-energy manufacturing to laboratory applications, industrial air purification systems…

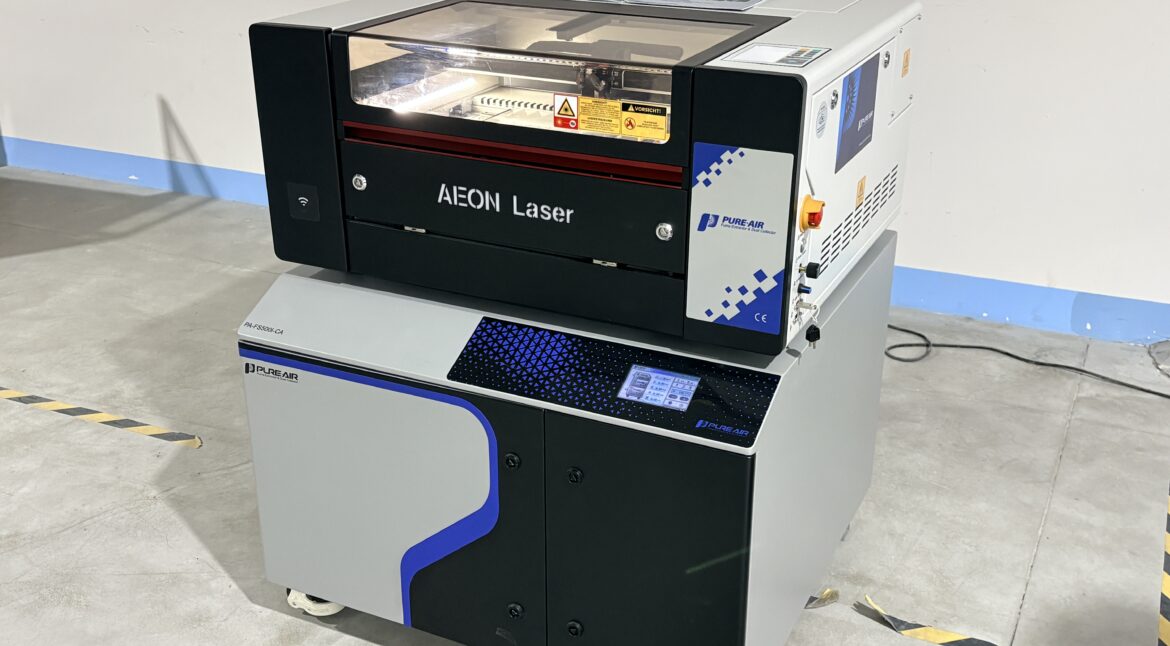

In order to better meet the needs of our global customers, PURE-AIR conducted a full series of real-world simulation tests covering multiple common laser processing materials—including rubber sheets, wood boards, MDF, acrylic, and leather. These materials were tested under laser cutting, engraving, and marking conditions to verify the performance of…

PURE-AIR — Professional Fume Extraction Solutions for the Electronics Manufacturing Industry As electronic products become increasingly precise and compact, soldering remains an essential process in manufacturing. However, many factories overlook a critical issue — the fumes generated during electronic soldering can significantly impact worker health, product quality, and the overall…

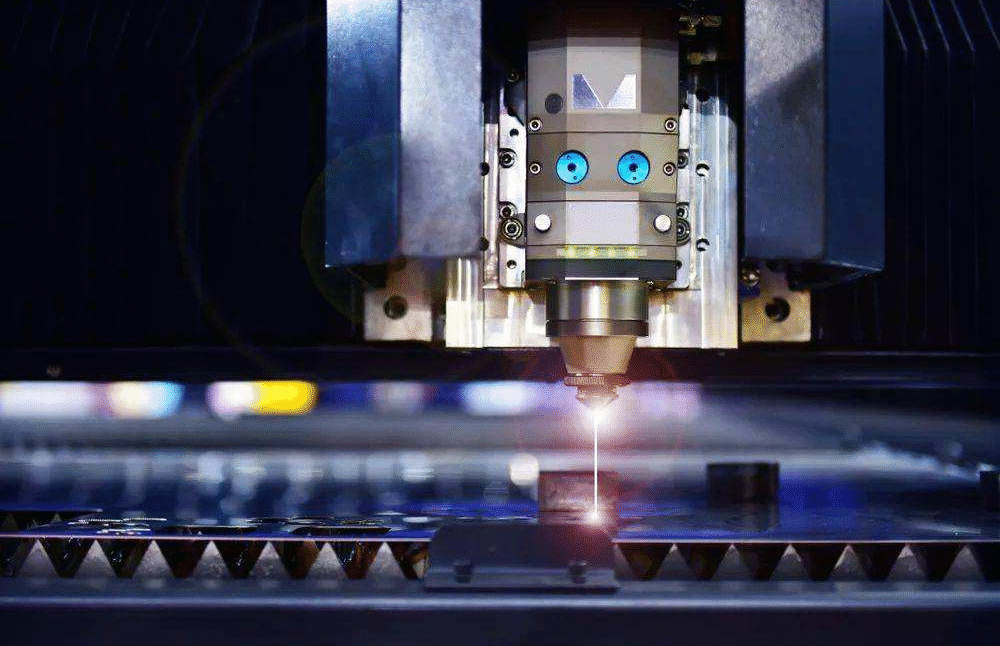

Laser cleaning has rapidly become one of the fastest-growing surface-treatment technologies in modern manufacturing. With advantages such as precision removal, zero consumables, and environmentally friendly operation, it is now widely used in aerospace, automotive manufacturing, mold repair, cultural relics restoration, and metal processing. However, while laser cleaning eliminates chemical solvents…

Today, PURE-AIR was honored to welcome our strategic partner from Russia — the ASRUS X team — to our headquarters for a full-day technical exchange and cooperation meeting. This visit marks another solid step forward in our global market expansion and deep collaboration in industrial fume purification technologies. A Warm…

For years, many companies have relied on vent-to-air or centralized exhaust systems for their fume extraction needs. However, with the rise of agile manufacturing practices, portable extraction systems, like those designed by PURE-AIR, have become an increasingly popular choice among businesses looking for flexibility and performance. While centralized systems remain…

PURE-AIR Industrial Dust Purification System: 14 Years of Ingenious Research and Development, Reshaping the Standard for Industrial Air Purification with Core Technology —Leading the Global Clean Production Revolution with Innovative Technology and Superior Quality In modern industrial production environments, smoke, dust, and harmful gases generated by processes like welding, laser…

The Hidden Dangers of Laser Smoke — and How PURE-AIR Protects Your Workspace Invisible Smoke, Visible Damage During laser cutting, engraving, and marking, the intense heat generated by the laser beam vaporizes materials like metal, plastic, or acrylic. This process releases microscopic smoke particles, dust, and harmful gases — including…

PURE-AIR: Setting a New Benchmark Beyond BOFA In the global fume extraction industry, BOFA has long been regarded as a well-known name. However, as technology advances and industrial needs become more demanding, customers are seeking solutions that not only match but surpass the industry standard. That’s where PURE-AIR stands out.…

Laser cutting has revolutionized modern manufacturing with its speed, efficiency, and precision. Yet, behind every spark and every perfect cut, there lies an invisible but serious cost: ultrafine metal fumes and dust. Did you know? The particles generated during laser processing can be up to one-hundredth the size of PM2.5…