Fume Extraction Solutions for Laser Cutting Machines Introduction Laser cutting machines are widely used in metal processing, signage production, electronics manufacturing, and industrial fabrication due to their high precision and efficiency. However, laser cutting also generates a significant amount of smoke, fine particulate matter, and harmful gases, which pose serious…

What Is an Industrial Fume Extractor and How Does It Work? Introduction In modern manufacturing environments, airborne pollutants such as smoke, fumes, fine dust, and volatile organic compounds (VOCs) are unavoidable by-products of industrial processes. Laser cutting, welding, soldering, engraving, and chemical processing all generate hazardous fumes that can pose…

Industrial Fume Extractor Manufacturer with 14 Years of Expertise | PURE-AIR Professional Industrial Fume Extraction Solutions for Modern Manufacturing With the rapid development of modern manufacturing, industrial processes such as laser cutting, laser marking, laser engraving, welding, soldering, and electronic production generate large amounts of smoke, dust, and hazardous airborne…

Why They Are Becoming a Global Manufacturing Essential As global manufacturing continues to evolve and environmental regulations become stricter, fume extractors are rapidly shifting from an optional accessory to a mandatory standard across multiple industries.From laser processing to electronic soldering, from new-energy manufacturing to laboratory applications, industrial air purification systems…

PURE-AIR Helps You See the “Invisible Hazards” In modern manufacturing, laser marking, cutting, and engraving have become mainstream processes known for high efficiency and precision. However, in most production workshops, a critical issue is quietly being overlooked—microscopic fumes and chemical pollutants generated during laser processing. These substances are often invisible…

In modern industrial manufacturing, laser marking has become a core technology for product traceability, anti-counterfeiting, and brand identification. Whether it’s electronic components, metal parts, automotive accessories, or plastic packaging, laser marking is widely used due to its advantages of high precision, high speed, and permanent marking. However, while many companies…

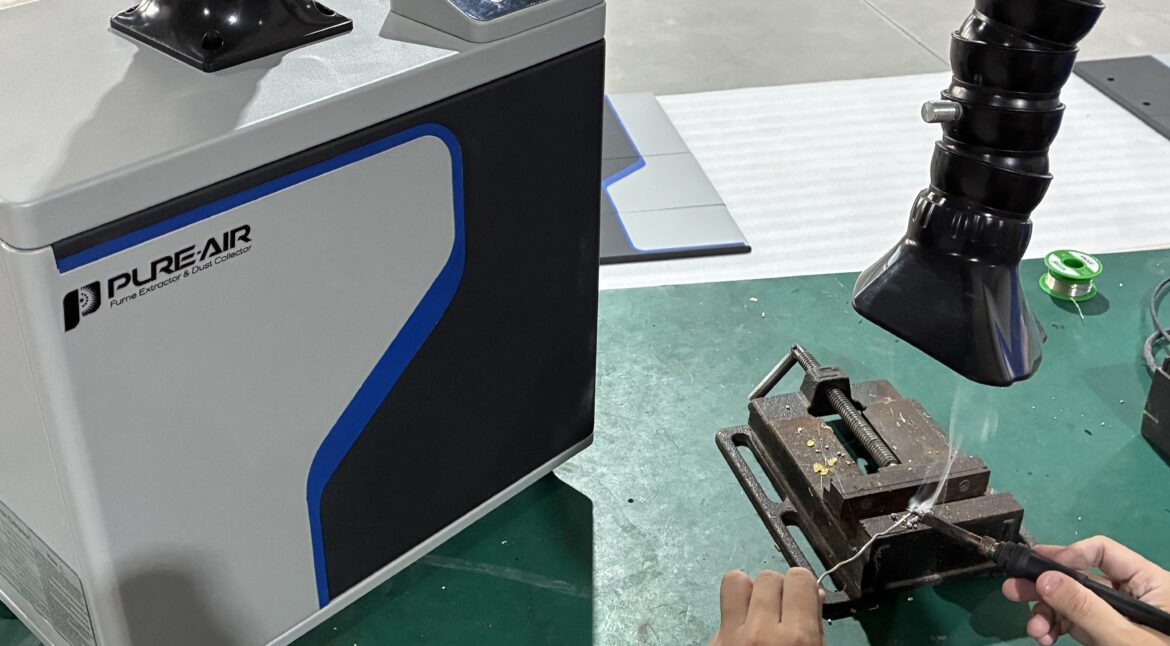

In modern manufacturing environments, processes like laser marking and electronics soldering have become essential to ensure precision, efficiency, and innovation. However, both processes generate harmful fumes, particulates, and chemical residues that can threaten operator health, product quality, and equipment longevity. At PURE-AIR, we provide advanced industrial fume extraction systems specifically…

Today, PURE-AIR was honored to welcome our strategic partner from Russia — the ASRUS X team — to our headquarters for a full-day technical exchange and cooperation meeting. This visit marks another solid step forward in our global market expansion and deep collaboration in industrial fume purification technologies. A Warm…

Laser technology delivers unparalleled precision and speed in cutting, welding, and marking. But the very process that vaporizes material creates an insidious byproduct: laser-generated fumes. These are not mere nuisance smoke; they are a complex plume of ultrafine particles and toxic gases that directly threaten your most valuable assets—your expensive laser…

For the plastics industry, traditional marking methods cannot effectively leave long-term marks on products, so today’s plastics industry is using laser marking, a relatively advanced marking process. Plastic laser engraving machine has been widely used in many products. Plastic is a plastic material with high polymer melting point. In the…