In the pulse of modern industrial production, processes such as welding, laser cutting, and grinding create value while also generating visible and invisible byproducts—industrial fumes and hazardous gaseous pollutants. These fine particulate matters, often smaller than 20 microns in diameter, escape the naked eye yet can travel deep into the…

Why They Are Becoming a Global Manufacturing Essential As global manufacturing continues to evolve and environmental regulations become stricter, fume extractors are rapidly shifting from an optional accessory to a mandatory standard across multiple industries.From laser processing to electronic soldering, from new-energy manufacturing to laboratory applications, industrial air purification systems…

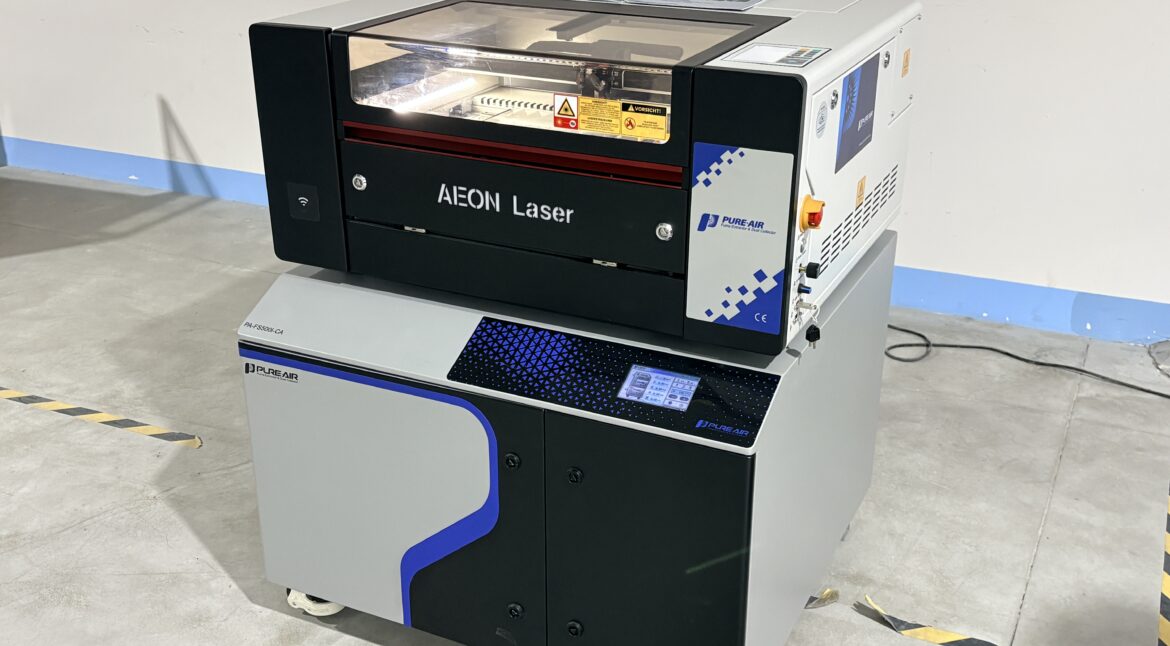

PURE-AIR Helps You See the “Invisible Hazards” In modern manufacturing, laser marking, cutting, and engraving have become mainstream processes known for high efficiency and precision. However, in most production workshops, a critical issue is quietly being overlooked—microscopic fumes and chemical pollutants generated during laser processing. These substances are often invisible…

In order to better meet the needs of our global customers, PURE-AIR conducted a full series of real-world simulation tests covering multiple common laser processing materials—including rubber sheets, wood boards, MDF, acrylic, and leather. These materials were tested under laser cutting, engraving, and marking conditions to verify the performance of…

Laser cleaning has rapidly become one of the fastest-growing surface-treatment technologies in modern manufacturing. With advantages such as precision removal, zero consumables, and environmentally friendly operation, it is now widely used in aerospace, automotive manufacturing, mold repair, cultural relics restoration, and metal processing. However, while laser cleaning eliminates chemical solvents…

In modern industrial manufacturing, laser marking has become a core technology for product traceability, anti-counterfeiting, and brand identification. Whether it’s electronic components, metal parts, automotive accessories, or plastic packaging, laser marking is widely used due to its advantages of high precision, high speed, and permanent marking. However, while many companies…

In today’s advanced manufacturing industry, laser marking has become one of the most widely used processes for product identification and traceability. From electronics and automotive parts to medical devices and metal tools, laser marking ensures precision, durability, and high production efficiency. However, behind every clean and precise mark lies a…

In modern industrial production systems, manufacturing processes such as welding, laser cutting, and grinding generate industrial fumes and dust that have become critical factors affecting sustainable business development. These complex pollutants, composed of metal oxides, toxic gases, and suspended particulate matter, not only directly threaten employee health but also damage…

Industrial Fume Purification: Comprehensive Solutions for Enhanced Workshop Air Quality In modern industrial production environments, fumes and dust generated during processes like welding, cutting, and grinding pose significant threats to both employee health and production efficiency. These microscopic pollutants not only harm respiratory systems but also impact equipment lifespan and…

Laser technology delivers unparalleled precision and speed in cutting, welding, and marking. But the very process that vaporizes material creates an insidious byproduct: laser-generated fumes. These are not mere nuisance smoke; they are a complex plume of ultrafine particles and toxic gases that directly threaten your most valuable assets—your expensive laser…