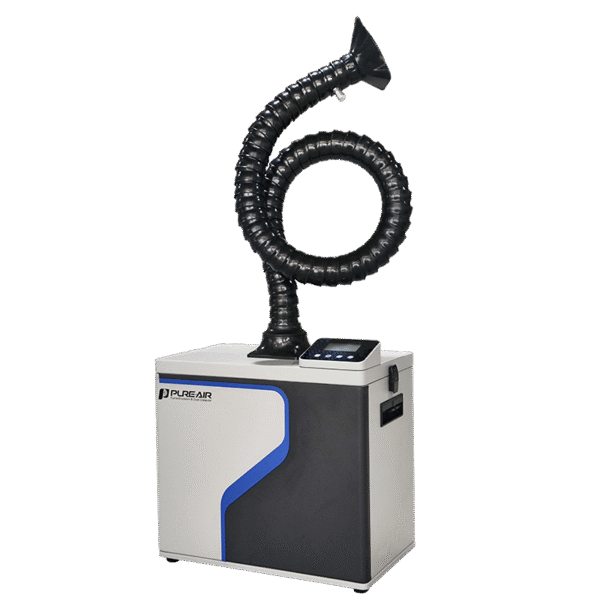

Advanced Laser Smoke Purification Equipment

The D Series laser smoke purification equipment uses -12000Pa negative pressure to capture smoke efficiently. Multi-stage filters remove 0.3-micron particles. Silicon dust, fluoride, and harmful gases are filtered with 99.99% efficiency. The clean air meets Class 1000 precision workshop standards.