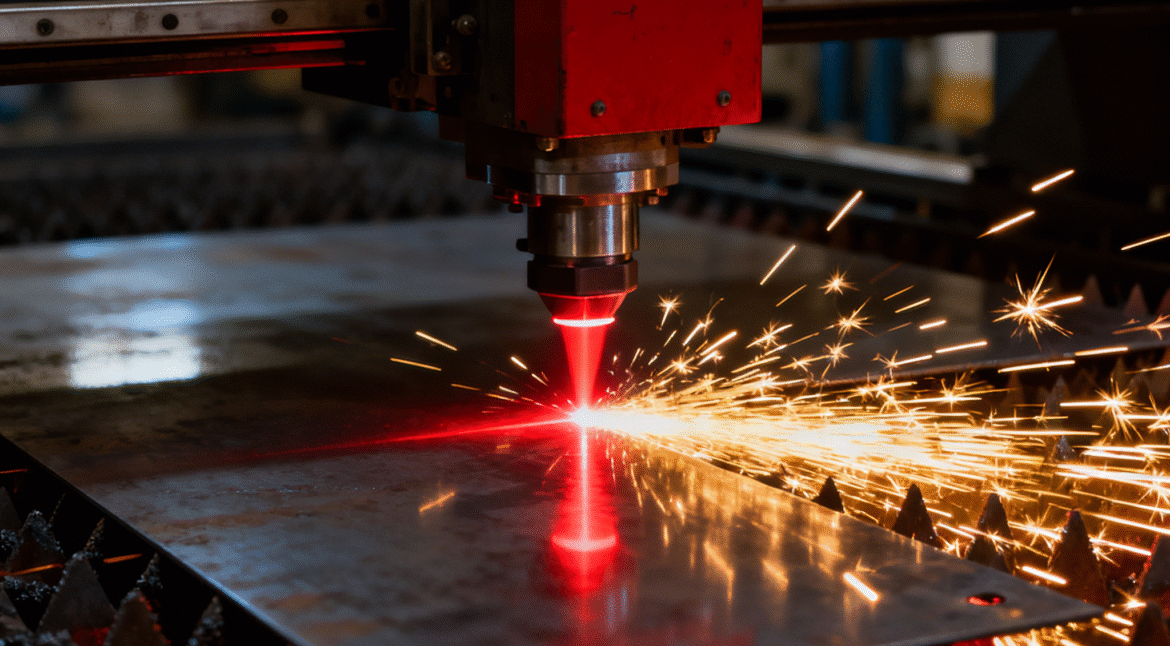

In the modern precision manufacturing landscape, stainless steel processing stands as a cornerstone of high-end engineering. However, the very alloying elements that make stainless steel resilient—specifically chromium and nickel—create a formidable health hazard when subjected to the extreme heat of welding and laser cutting. During these processes, the air is not merely “smoky”; it is saturated with toxic Hexavalent Chromium (Cr(VI)) aerosols and ultra-fine metallic nano-dust.

Standard workshop ventilation often fails to address these invisible killers. To ensure the safety of operators and compliance with stringent environmental regulations, a single-layer filtration approach is insufficient. Instead, a sophisticated “Chemical + Physical” composite purification strategy is required. This article examines how a high-performance workshop fume extractor utilizes the synergy of chemical molecular adsorption and multi-stage physical interception to neutralize the most dangerous industrial pollutants at their source.

1. The Invisible Threat: Why Stainless Steel Fumes are “Special.”

When you weld or laser-cut stainless steel, the high-energy beam or arc vaporizes the metal. As this vapor cools, it condenses into extremely fine particulate matter.

The Hazard of Hexavalent Chromium (Cr(VI))

Unlike common iron oxide dust, the chromium in stainless steel oxidizes into Hexavalent Chromium. This is a known Group 1 carcinogen. Because Cr(VI) often exists as an aerosol—a mixture of liquid droplets and solid particles—it can bypass the nose and throat, penetrating deep into the alveolar regions of the lungs.

The Challenge of Nano-Dust

Laser cutting generates particles in the sub-micron range, often as small as 10 to 100 nanometers. These “nano-dust” particles are so light that they remain suspended in the workshop air for hours, resisting gravity and overwhelming traditional mechanical filters that rely on simple “sieving” effects.

2. The Physical Defense: Multi-Stage Precision Interception

A professional workshop fume extractor must employ a multi-layered physical defense to handle the varying sizes of particulate matter generated during the cutting and welding cycle.

High-Efficiency Particulate Air (HEPA) & ULPA

The backbone of physical purification is the HEPA or ULPA filter.

-

HEPA (H13/H14): Captures 99.97% to 99.99% of particles as small as 0.3 microns.

-

ULPA (U15/U16): For high-precision laser cutting, ULPA filters provide even deeper protection, capturing particles down to 0.1 microns with 99.999% efficiency.

The Importance of Pre-Filtration

If you expose a HEPA filter directly to raw welding smoke, it will clog within hours. Therefore, a robust system uses a multi-level physical approach:

-

G4/F7 Pre-filter: Captures large sparks and coarse dust.

-

F9 Medium-efficiency Filter: Targets the 1–5 micron range, significantly extending the lifespan of the expensive HEPA stage.

3. The Chemical Shield: Molecular Neutralization of Cr(VI)

Physical filters are excellent at catching “dust,” but they cannot always neutralize the reactive chemical nature of Hexavalent Chromium aerosols or the ozone gas produced during high-frequency welding. This is where Chemical Filtration becomes indispensable.

Chemisorption Technology

By integrating chemical filtration media (such as Purafil or specialized permanganate-impregnated alumina), the workshop fume extractor transitions from a “catcher” to a “neutralizer.”

-

Oxidation-Reduction Reaction: The chemical media reacts with Hexavalent Chromium at the molecular level. It converts toxic gases and reactive aerosols into stable, non-toxic solids trapped within the porous structure of the media.

-

Ozone and VOC Adsorption: Welding often produces ozone and volatile organic compounds (VOCs) from surface oils. The chemical layer adsorbs these odors and gases, ensuring the air returned to the workshop is not only dust-free but chemically “pure.”

4. The Synergy: How “Chemical + Physical” Works Together

The true innovation lies in the “Composite Architecture.” When a workshop fume extractor combines these two methods, it creates a total safety envelope.

-

Step 1: The Mechanical Trap. The nano-dust particles collide with HEPA fibers through Brownian motion and interception, locking the solid heavy metal particles in place.

-

Step 2: The Molecular Attack. As the air passes through the chemical module, the toxic Cr(VI) molecules and ozone gas come into contact with the active chemical agents. A permanent chemical bond forms, ensuring that the toxins cannot “leak” back into the environment.

-

Step 3: The Carbon Polish. A final layer of activated carbon often follows to remove any trace smells, resulting in hospital-grade air quality for the industrial floor.

5. Optimizing Workshop ROI through Smart Extraction

Beyond safety, a high-end workshop fume extractor offers significant economic benefits for the modern factory.

-

Extended Filter Life: By using a “Chemical + Physical” balance, the system prevents the HEPA filter from being overwhelmed by reactive gases, which can otherwise degrade the filter media over time.

-

Reduced Energy Costs: High-quality extractors use variable frequency drives (VFD) to adjust suction based on the actual welding or cutting load. This reduces electricity consumption while maintaining the “Capture Velocity” required to pull fumes away from the operator’s breathing zone.

-

Reduced Facility Maintenance: By capturing nano-dust at the source, you prevent the accumulation of metallic dust on expensive electronics and CNC controllers, reducing the risk of short circuits and equipment downtime.

6. Conclusion: Choosing the Ultimate Protection

Stainless steel welding and laser cutting demand more than just a “vacuum cleaner.” They require a biological and chemical defense system. By choosing a workshop fume extractor that integrates multi-stage HEPA/ULPA physical filtration with advanced chemisorption layers, you are not just filtering smoke—you are neutralizing a toxic threat.

In the pursuit of industrial excellence, clean air is the most valuable raw material. The composite purification approach ensures that your workshop remains a place of precision and health, where the “Golden Standard” of production is matched by the “Diamond Standard” of safety.