Airborne fumes have become a major concern in modern industrial environments. Manufacturing lines, welding stations, laser processing rooms, and electronics assembly areas release complex aerosols that contain ultra-fine particles. These particles often measure far below one micron and can easily enter sensitive equipment or the human respiratory system. Therefore, industries…

Pleated dust filter solutions play a central role in modern industrial dust collection. As production environments grow more complex, filtration demands continue to rise. Industries now face finer particles, higher airflow, and continuous-duty operations that strain conventional filter media. Because of these challenges, the choice of filter material becomes a…

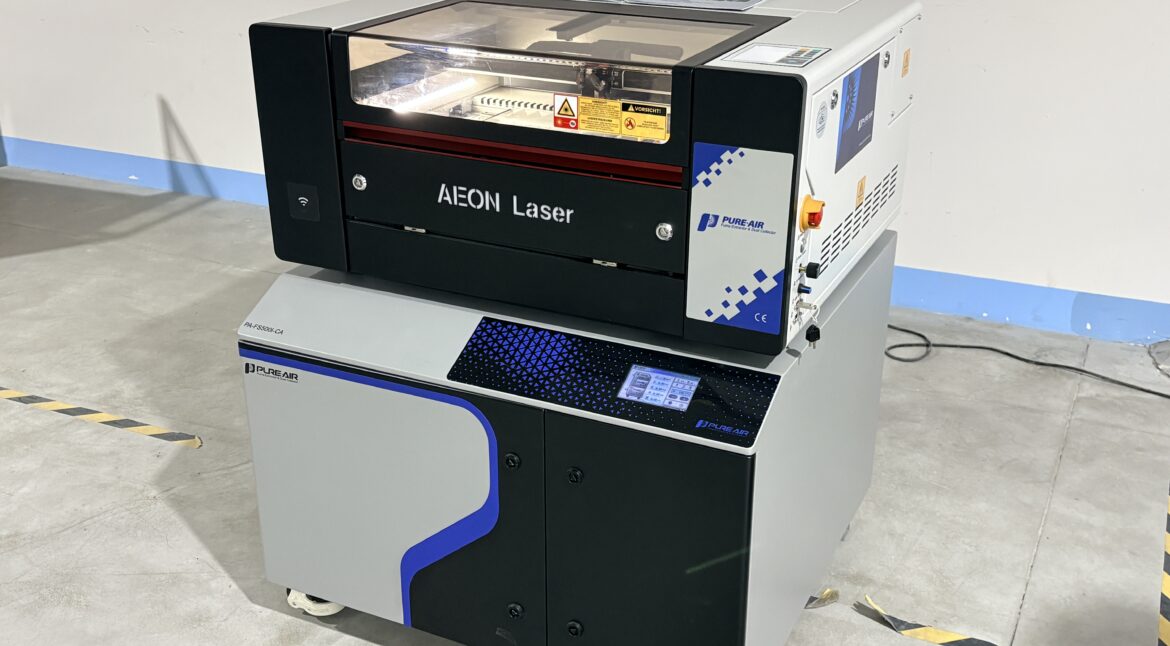

PURE-AIR Helps You See the “Invisible Hazards” In modern manufacturing, laser marking, cutting, and engraving have become mainstream processes known for high efficiency and precision. However, in most production workshops, a critical issue is quietly being overlooked—microscopic fumes and chemical pollutants generated during laser processing. These substances are often invisible…

In the bustling industrial workshop filled with the roar of machinery and flying sparks, what we see are finished components and efficient production lines. Yet, we often overlook the “invisible threats” in the air—both visible and invisible industrial fumes and dust. These are not merely hazards to equipment precision and…

CNC milling shops manage tough chip loads every day. Although many shops invest in powerful spindles, rigid tooling, and stable machine structures, they often ignore the most basic requirement for stable cutting conditions: controlled airflow. Since chip formation produces both heavy metal fragments and fine airborne particulates, every CNC environment…

Modern factories rely on stable production, predictable maintenance schedules, and clean working conditions. Therefore, air quality control has become a mission-critical requirement. However, many workshops still underestimate the diversity of airborne contaminants. Welding shops focus on fumes, CNC machining plants worry about fine powder, and battery factories fight ultra-fine particles.…

In order to better meet the needs of our global customers, PURE-AIR conducted a full series of real-world simulation tests covering multiple common laser processing materials—including rubber sheets, wood boards, MDF, acrylic, and leather. These materials were tested under laser cutting, engraving, and marking conditions to verify the performance of…

A Technical Breakdown for Industrial Buyers, Procurement Teams, and Factory Decision-Makers In modern industrial environments, airborne pollutants have become a critical challenge. Factories across machining, welding, laser cutting, electronics assembly, and 3D printing all generate complex mixtures of smoke, oil mist, volatile organic compounds, and fine metal particles. Because these…

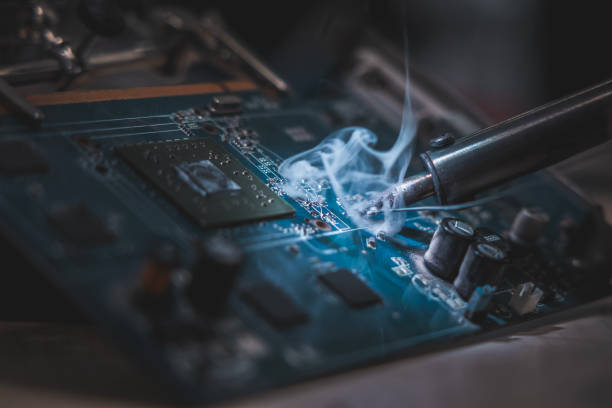

Modern PCB assembly relies on speed, consistency, and extremely clean production environments. As factories increase automation and throughput, they also face growing contamination risks. PCB soldering, conformal coating, wave soldering, and laser marking release complex fumes that can threaten worker health and equipment reliability. Because these fumes contain particulate and…

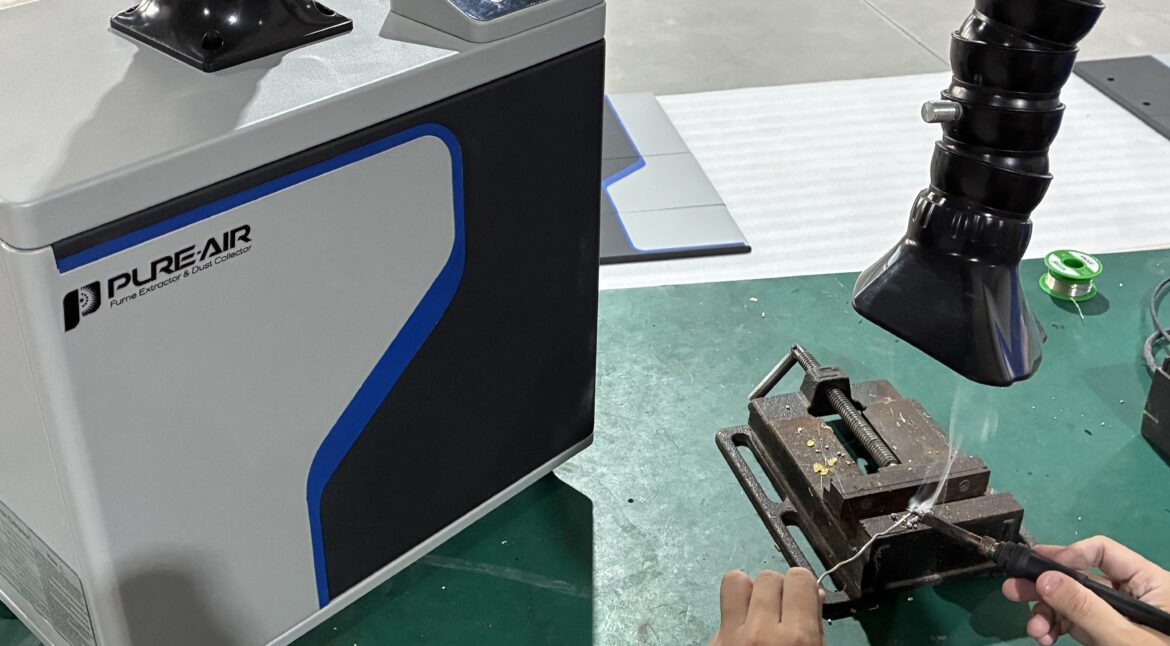

PURE-AIR — Professional Fume Extraction Solutions for the Electronics Manufacturing Industry As electronic products become increasingly precise and compact, soldering remains an essential process in manufacturing. However, many factories overlook a critical issue — the fumes generated during electronic soldering can significantly impact worker health, product quality, and the overall…