Core Structure of PURE-AIR Industrial Fume Extractor

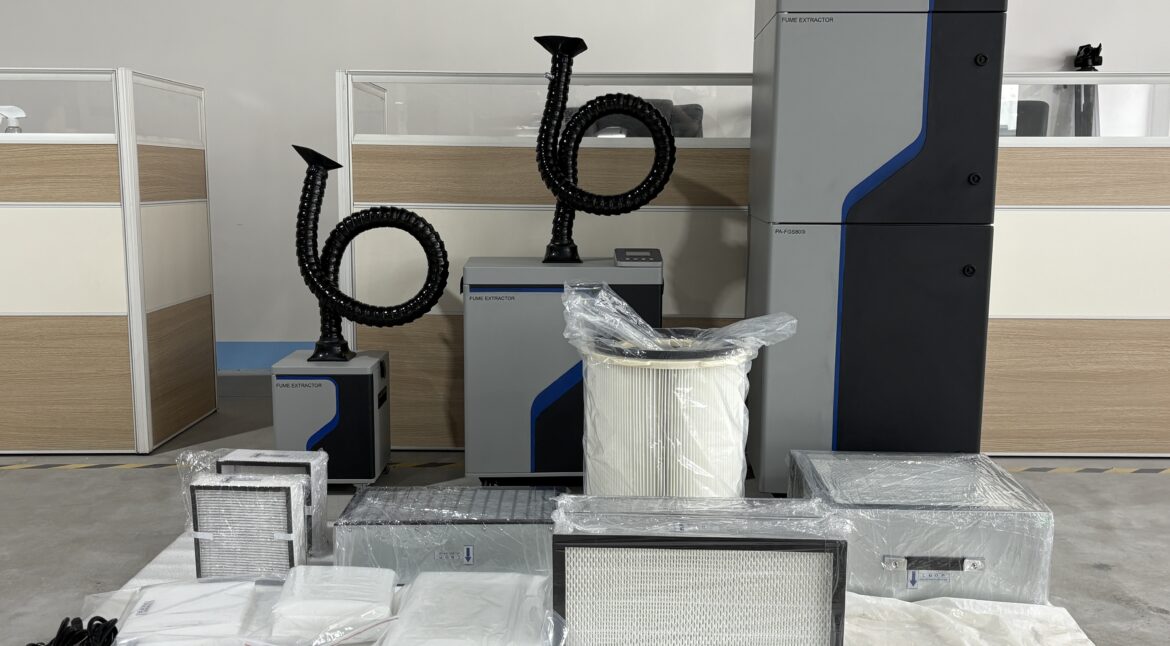

Introduction

The performance and reliability of an industrial fume extractor depend not only on filtration efficiency, but also on the overall system structure and component integration. A well-engineered internal structure ensures stable airflow, efficient pollutant capture, long service life, and safe continuous operation.

As a professional industrial fume extractor manufacturer with over 14 years of R&D and production experience, PURE-AIR designs every system based on industrial operating conditions. From airflow architecture to electrical integration, each structural module is optimized to deliver consistent and high-performance air purification.

Image suggestion:

Exploded view of industrial fume extractor internal structure

Overall Structural Architecture

The core structure of a PURE-AIR industrial fume extractor is designed around a modular airflow path, allowing contaminated air to move efficiently through each functional zone.

The main structural modules include:

-

Air inlet and source capture interface

-

Pre-filtration section

-

Main filtration module

-

High negative pressure fan chamber

-

Intelligent control and electrical system

-

Structural housing and noise insulation

This integrated layout minimizes airflow resistance while maximizing filtration performance.

Image suggestion:

Diagram showing airflow path inside fume extractor

High Negative Pressure Fan System

At the heart of the PURE-AIR fume extractor is the high negative pressure centrifugal fan system, which provides stable suction for industrial applications.

Structural Features:

-

Precision-balanced impeller design

-

Industrial-grade motor for continuous duty

-

Optimized airflow channels to reduce turbulence

-

Reinforced fan housing for vibration control

By manufacturing core fan components in-house, PURE-AIR ensures long-term performance stability and consistent airflow output.

Image suggestion:

High negative pressure centrifugal fan module

Multi-Stage Filtration Module

PURE-AIR fume extractors utilize a multi-stage filtration structure to handle different particle sizes and pollutant types.

Filtration Layers Include:

1. Pre-Filter Layer

Captures large particles, sparks, and heavy dust, protecting downstream filters and extending service life.

2. High-Efficiency Main Filter

Removes fine smoke particles and industrial dust with high filtration efficiency.

3. Activated Carbon Filter (Optional)

Adsorbs odors, VOCs, and chemical vapors commonly found in laser cutting and soldering applications.

This layered structure ensures both high purification efficiency and low operating cost.

Image suggestion:

Exploded view of multi-stage filtration system

Intelligent Control and Electrical System

PURE-AIR integrates its proprietary PIPS Intelligent Purification System into the core structure.

System Capabilities:

-

Real-time airflow and pressure monitoring

-

Filter saturation detection

-

System status diagnostics

-

Maintenance reminder functions

The electrical control architecture is designed for industrial safety standards and stable long-term operation.

Image suggestion:

Control panel interface of industrial fume extractor

Structural Housing and Noise Reduction Design

The external housing of PURE-AIR industrial fume extractors is engineered for durability and acoustic performance.

Structural Advantages:

-

Industrial-grade metal housing

-

Reinforced frame structure

-

Internal noise-absorbing materials

-

Easy-access maintenance panels

This design ensures mechanical stability while maintaining comfortable noise levels in industrial environments.

Image suggestion:

Industrial fume extractor housing and internal insulation structure

Modular Design for Maintenance and Scalability

PURE-AIR adopts a modular structural concept that allows:

-

Easy filter replacement

-

Simplified maintenance

-

Flexible configuration for different applications

-

Scalable upgrades

This design philosophy reduces downtime and improves long-term operational efficiency.

Manufacturing and Assembly Quality Control

All PURE-AIR industrial fume extractors undergo:

-

Component-level inspection

-

Electrical safety testing

-

Airflow and pressure performance testing

-

Full system operation verification

Assembly is performed in-house to ensure strict quality control and consistent product performance.

Image suggestion:

PURE-AIR factory assembly and testing area

Conclusion

The core structure of a PURE-AIR industrial fume extractor reflects years of engineering optimization and manufacturing experience. From high negative pressure fan systems to intelligent filtration control, every component is designed to deliver stable, efficient, and long-lasting performance.

By combining structural innovation with in-house manufacturing expertise, PURE-AIR provides industrial air purification solutions that meet the demands of modern production environments.