Fume Extraction Solutions for Laser Cutting Machines

Introduction

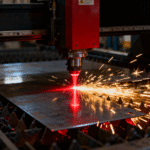

Laser cutting machines are widely used in metal processing, signage production, electronics manufacturing, and industrial fabrication due to their high precision and efficiency. However, laser cutting also generates a significant amount of smoke, fine particulate matter, and harmful gases, which pose serious risks to operator health, equipment performance, and workplace safety.

A dedicated fume extraction solution for laser cutting machines is essential to control these emissions at the source. As a professional industrial fume extractor manufacturer with over 14 years of R&D and production experience, PURE-AIR provides laser-specific fume extraction systems designed to meet the demanding requirements of modern industrial environments.

Image suggestion:

Laser cutting machine operating with visible smoke being extracted

What Types of Fumes Are Generated During Laser Cutting?

Laser cutting fumes vary depending on the processed material and laser type, but typically include:

-

Ultra-fine smoke particles (<1 micron)

-

Metal oxides from steel, stainless steel, and aluminum

-

Organic vapors and VOCs from plastics, acrylic, leather, and rubber

-

Odors and toxic gases released during thermal decomposition

These contaminants can remain airborne for long periods and easily bypass standard ventilation systems.

Image suggestion:

Different materials producing smoke during laser cutting

Why Standard Ventilation Is Not Enough

General workshop ventilation only dilutes airborne contaminants—it does not effectively capture fumes at the source. In laser cutting applications, this leads to:

-

Smoke spreading across the work area

-

Reduced cutting precision due to lens contamination

-

Increased maintenance costs for laser equipment

-

Health risks and regulatory compliance issues

A laser fume extraction system must be designed specifically for high smoke density, fine particles, and continuous operation.

Key Requirements for Laser Cutting Fume Extraction Systems

1. High Negative Pressure for Source Capture

Laser cutting produces dense smoke that must be captured immediately. High negative pressure ensures strong and stable suction at the cutting point, preventing fumes from escaping into the workspace.

Image suggestion:

High negative pressure suction capturing laser cutting fumes

2. Multi-Stage Filtration for Fine Particles

Laser fumes contain ultra-fine particles that require high-efficiency filtration. A professional system typically includes:

-

Pre-filters for large particles and sparks

-

High-efficiency cartridge or HEPA filters for fine smoke

-

Activated carbon filters for odors and VOCs (optional)

This configuration ensures both air quality and long filter service life.

3. Stable Performance Under Continuous Operation

Laser cutting machines often operate for long hours. Industrial fume extractors must be engineered for continuous duty with:

-

Industrial-grade motors

-

Heat-resistant components

-

Stable airflow under filter load

4. Compatibility with Machine Enclosures and Ducting

Laser fume extraction systems should integrate seamlessly with:

-

Fully enclosed laser cutting machines

-

Partial enclosures or open tables

-

Long or complex ducting layouts

Proper system matching is critical for maintaining extraction efficiency.

PURE-AIR Laser Cutting Fume Extraction Solutions

PURE-AIR designs laser-specific industrial fume extractors based on real production conditions.

Core Features:

-

Self-developed high negative pressure fan systems

-

Large-capacity, long-life filtration modules

-

PIPS Intelligent Purification System for performance monitoring

-

Robust electrical and control integration

-

Complete assembly and testing in-house

Our solutions are suitable for CO₂ lasers, fiber lasers, and mixed-material processing applications.

Image suggestion:

PURE-AIR laser fume extractor connected to laser cutting machine

Benefits of Professional Laser Fume Extraction

Implementing a dedicated laser fume extraction solution helps manufacturers:

-

Improve workplace air quality

-

Protect laser optics and mechanical components

-

Reduce downtime and maintenance costs

-

Comply with occupational safety and environmental standards

-

Enhance overall production efficiency

How to Choose the Right Laser Fume Extraction Solution

When selecting a fume extractor for laser cutting machines, consider:

-

Laser type and power level

-

Processed material and smoke density

-

Required airflow and negative pressure

-

Filtration efficiency and maintenance cost

-

Workshop layout and ducting distance

A professional manufacturer can provide customized solutions tailored to your specific application.