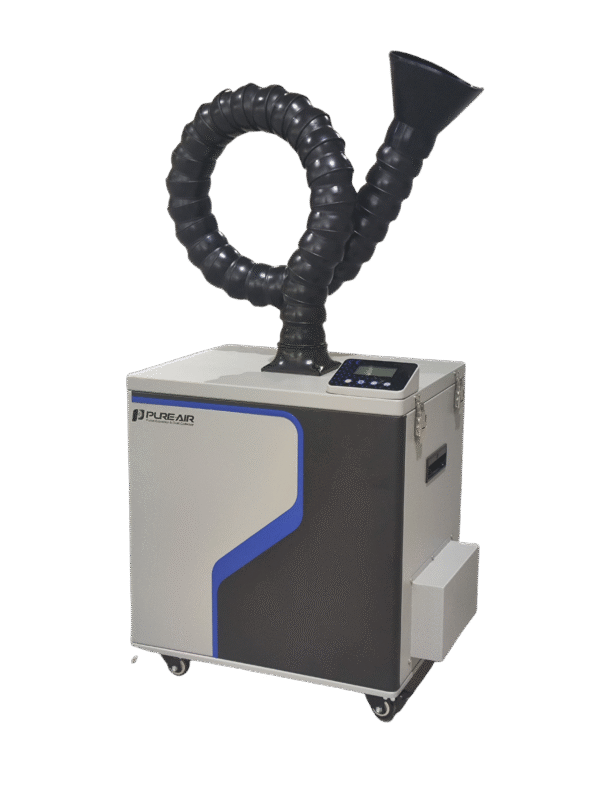

Precision Fume Extractor for Laser Marking Systems

PURE-AIR’s F Series Laser Marking and Coding Fume Extractor delivers reliable, efficient fume control for industrial marking systems. Compact, cost-effective, and built for safety, it ensures clean air and extended equipment life.

We welcome global distributors and dealers to join PURE-AIR — partner with us to bring professional fume extraction solutions to more industries worldwide!