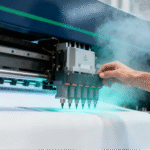

In traditional production management, industrial fumes are often seen as an unavoidable byproduct. However, from the perspective of modern intelligent manufacturing, untreated workshop fumes are quietly consuming a company’s core profits. Today, let’s analyze how a professional industrial fume purifier transforms from a “cost expenditure” into a “value investment,” safeguarding every cent of a company’s profit.

The Overlooked “Air Cost” – Five Hidden Losses from Workshop Fumes

1. Accelerated Equipment Depreciation, Soaring Maintenance Costs

-

Failure rates of precision equipment increase by 40% in polluted air

-

Lifespan of core components like optical sensors and laser heads shortens by 30–50%

-

Annual equipment maintenance budgets rise by an average of 25%

2. The “Silent Discount” on Production Efficiency

-

Reduced visibility leads to an 18% increase in operational errors

-

Unplanned breaks due to employee discomfort increase

-

Overall production line efficiency losses can reach 15%

3. The Hidden Rise in Quality Costs

-

Rework rates due to product surface contamination increase by 12%

-

Product qualification rates decline in high-end manufacturing scenarios

-

30% of customer complaints are related to cleanliness issues

4. Continuous Loss of Human Resources

-

Employee exit surveys show that the work environment is among the top three considerations

-

A clean workshop becomes a key competitive advantage when hiring skilled technicians

-

Potential legal costs arising from occupational disease risks

5. Invisible Damage to Brand Value

-

Workshop environment directly impacts partnership confidence during client visits

-

Non-compliance with increasingly stringent ESG (Environmental, Social, and Governance) standards

-

Exclusion from high-end supply chains due to environmental concerns

Chapter 2: From Cost to Investment – The True ROI of Fume Purifiers

Case Calculation: Annual Financial Analysis of a Medium-Sized Welding Workshop

-

Investment Cost: Installation of a professional fume purification system

-

Direct Returns (Within 12 Months):

-

Equipment maintenance costs reduced

-

Increased production efficiency creates

-

Quality improvement reduces losses

-

Health-related employee expenses decrease

-

-

Investment Payback Period: 8–14 months

-

Long-Term Value: Sustained annual returns exceed 300% of the system cost

Chapter 3: PURE-AIR’s Three Value Propositions – Beyond Purification, Creating Value

1. Intelligent Energy-Saving Technology: Making the Purification System “Self-Sustaining”

-

The PIPS intelligent regulation system saves 40% on energy consumption

-

Smart on-demand operation reduces unnecessary consumption

-

Energy savings over three years can cover equipment upgrade costs

2. Modular Long-Life Design: Reducing Total Lifecycle Costs

-

Proprietary “triple-life” filter technology

-

Modular design reduces maintenance time by 60%

-

Equipment lifespan extended to over 10 years

3. Data Visualization Management System: Making Air Value “Visible”

-

Real-time monitoring of air quality and energy consumption data

-

Automatic generation of purification efficiency reports

-

Provides data support for corporate ESG reporting

Chapter 4: Choices of Industry Pioneers – They Are Already Ahead

-

An Automotive Manufacturing Benchmark Company integrated a comprehensive purification system as part of its production standards, successfully entering the European high-end supply chain

-

A Precision Electronics Manufacturer improved product yield by 2.3 percentage points after investing in workshop purification, generating annual profits over five times the equipment investment

-

A Leading Food Packaging Company leveraged its “transparent, clean workshop” as a marketing highlight, securing additional orders from international clients

Chapter 5: Your Next Steps – From Assessment to Decision

We offer a three-step value assessment service:

Step 1: Free Air Value Diagnosis

-

Comprehensive testing of workshop air quality

-

Professional assessment of hidden costs

-

Preliminary calculation of investment returns

Step 2: Customized Value Solution

-

Industry-specific solutions

-

Detailed financial return analysis

-

Phased implementation recommendations

Step 3: Worry-Free Value Realization

-

Professional installation and commissioning

-

Employee operation training

-

Ongoing optimization services