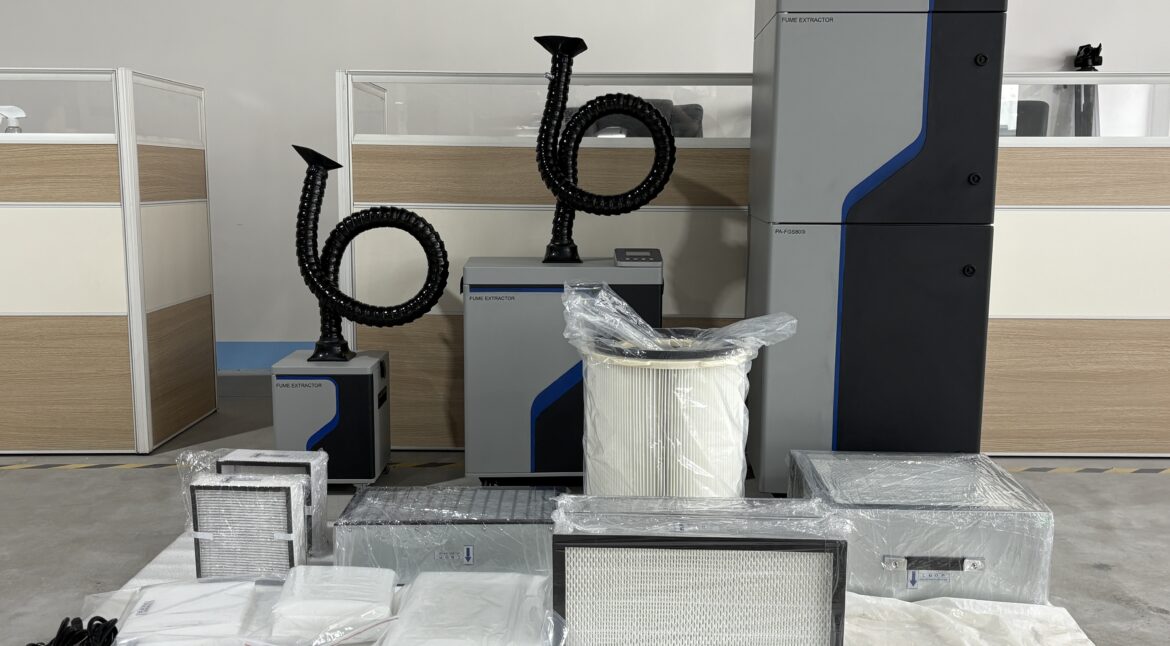

Core Structure of PURE-AIR Industrial Fume Extractor Introduction The performance and reliability of an industrial fume extractor depend not only on filtration efficiency, but also on the overall system structure and component integration. A well-engineered internal structure ensures stable airflow, efficient pollutant capture, long service life, and safe continuous operation.…

How to Control Soldering Smoke in Electronics Manufacturing Introduction Soldering is a core process in electronics manufacturing, used extensively in PCB assembly, component repair, and production lines. However, soldering operations generate smoke, fine particles, and chemical vapors that pose serious risks to operator health, product quality, and workplace compliance. Effective…

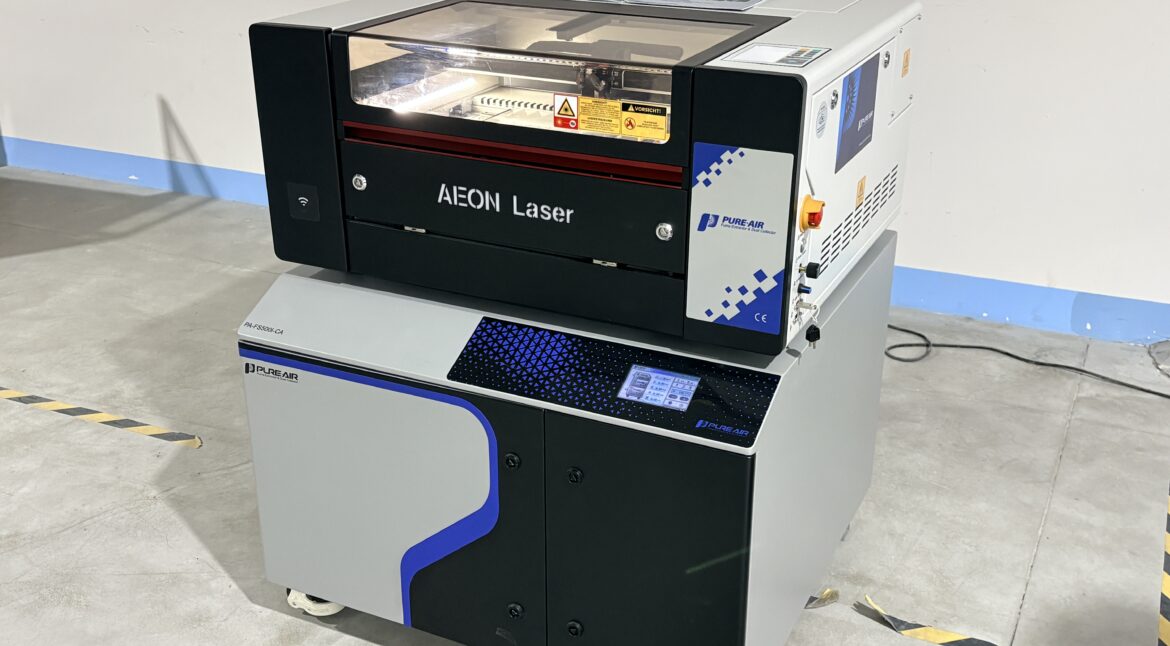

Fume Extraction Solutions for Laser Cutting Machines Introduction Laser cutting machines are widely used in metal processing, signage production, electronics manufacturing, and industrial fabrication due to their high precision and efficiency. However, laser cutting also generates a significant amount of smoke, fine particulate matter, and harmful gases, which pose serious…

Introduction Industrial production processes generate a wide range of airborne pollutants that are often invisible but highly hazardous. Smoke, dust, and harmful fine particles are common by-products of laser processing, welding, soldering, grinding, and other manufacturing operations. Without effective control, these contaminants can seriously impact worker health, equipment reliability, and…

What Is an Industrial Fume Extractor and How Does It Work? Introduction In modern manufacturing environments, airborne pollutants such as smoke, fumes, fine dust, and volatile organic compounds (VOCs) are unavoidable by-products of industrial processes. Laser cutting, welding, soldering, engraving, and chemical processing all generate hazardous fumes that can pose…

Industrial Fume Extractor Manufacturer with 14 Years of Expertise | PURE-AIR Professional Industrial Fume Extraction Solutions for Modern Manufacturing With the rapid development of modern manufacturing, industrial processes such as laser cutting, laser marking, laser engraving, welding, soldering, and electronic production generate large amounts of smoke, dust, and hazardous airborne…

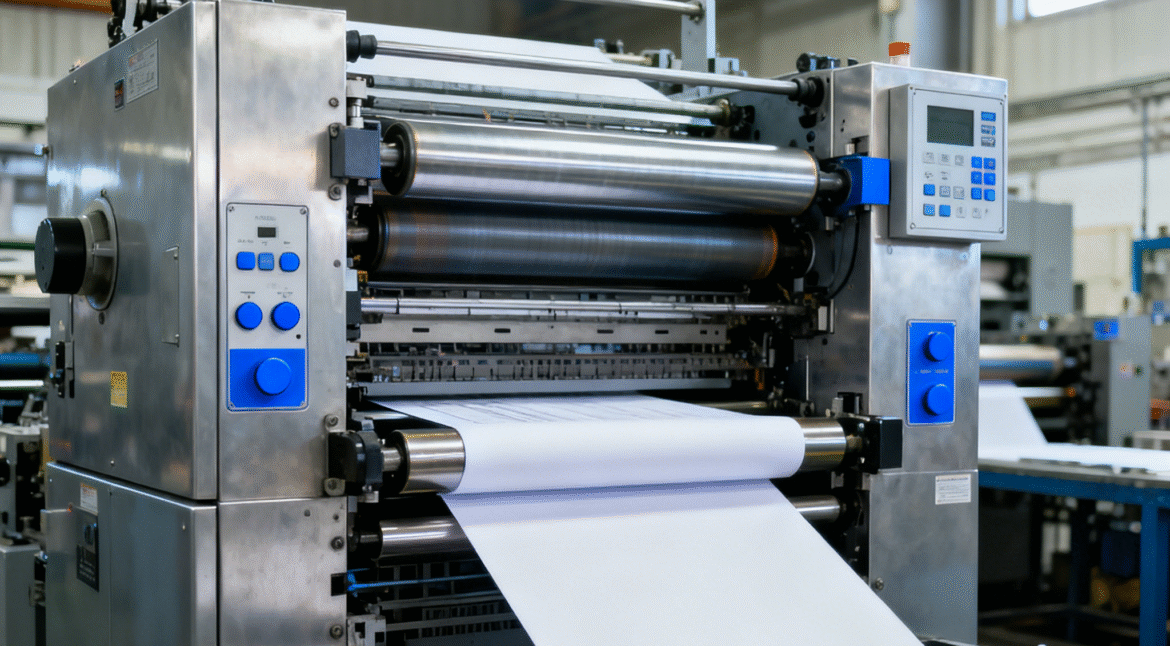

In printing workshops, people often talk about that familiar “smell,” originating from inks, varnishes, adhesives, and solvents. Many believe that eliminating these odors equates to removing all health risks. However, a deep dive into safety data sheets reveals a far more complex reality—many emissions of concern are invisible and may…

Why They Are Becoming a Global Manufacturing Essential As global manufacturing continues to evolve and environmental regulations become stricter, fume extractors are rapidly shifting from an optional accessory to a mandatory standard across multiple industries.From laser processing to electronic soldering, from new-energy manufacturing to laboratory applications, industrial air purification systems…

PURE-AIR Helps You See the “Invisible Hazards” In modern manufacturing, laser marking, cutting, and engraving have become mainstream processes known for high efficiency and precision. However, in most production workshops, a critical issue is quietly being overlooked—microscopic fumes and chemical pollutants generated during laser processing. These substances are often invisible…

In order to better meet the needs of our global customers, PURE-AIR conducted a full series of real-world simulation tests covering multiple common laser processing materials—including rubber sheets, wood boards, MDF, acrylic, and leather. These materials were tested under laser cutting, engraving, and marking conditions to verify the performance of…