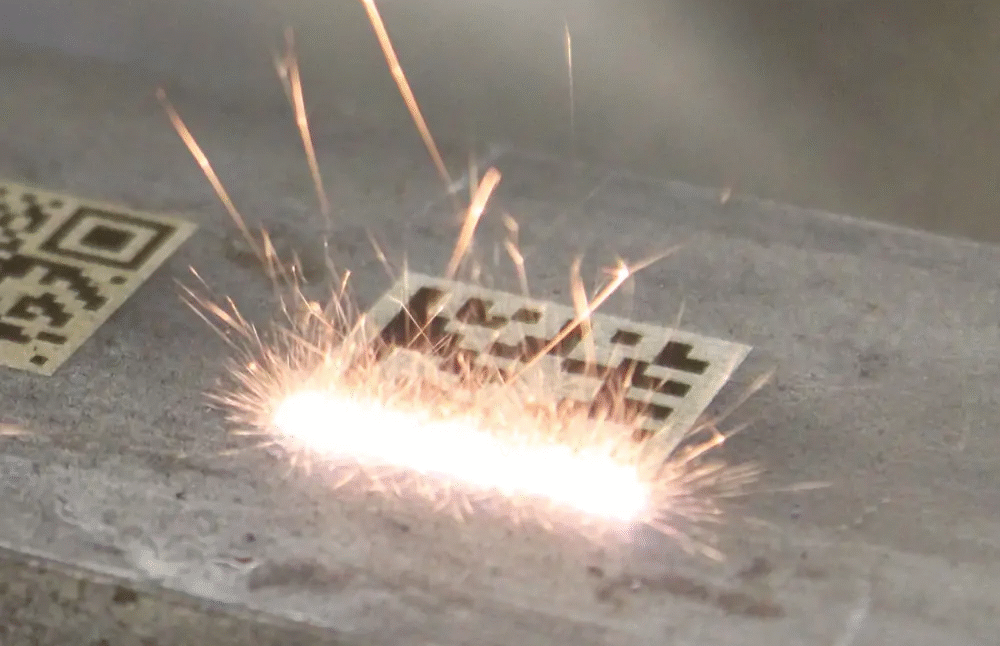

In order to better meet the needs of our global customers, PURE-AIR conducted a full series of real-world simulation tests covering multiple common laser processing materials—including rubber sheets, wood boards, MDF, acrylic, and leather. These materials were tested under laser cutting, engraving, and marking conditions to verify the performance of…

Today, PURE-AIR was honored to welcome our strategic partner from Russia — the ASRUS X team — to our headquarters for a full-day technical exchange and cooperation meeting. This visit marks another solid step forward in our global market expansion and deep collaboration in industrial fume purification technologies. A Warm…

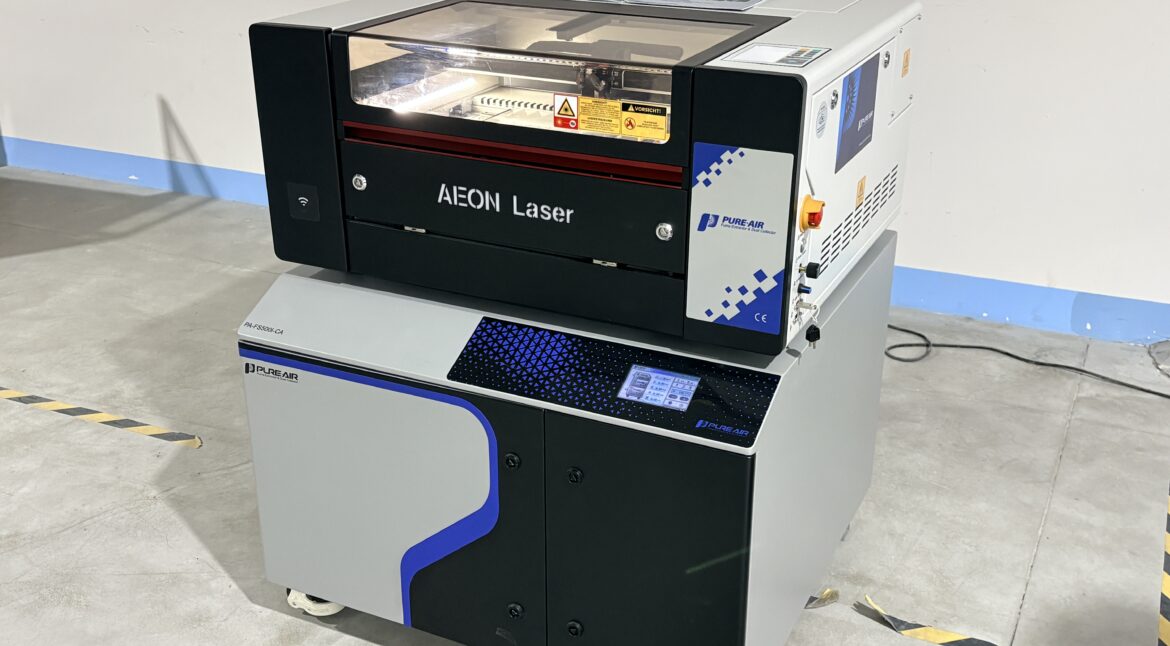

Why Factories Need Laser Fume Extraction Systems Protecting Health, Equipment, and Compliance in Modern Manufacturing In today’s advanced manufacturing environment, laser technology is widely used in cutting, marking, welding, and engraving. While lasers bring higher precision and efficiency, the smoke and ultrafine dust released during processing can create silent but…

PURE-AIR Industrial Dust Purification System: 14 Years of Ingenious Research and Development, Reshaping the Standard for Industrial Air Purification with Core Technology —Leading the Global Clean Production Revolution with Innovative Technology and Superior Quality In modern industrial production environments, smoke, dust, and harmful gases generated by processes like welding, laser…

The Hidden Dangers of Laser Smoke — and How PURE-AIR Protects Your Workspace Invisible Smoke, Visible Damage During laser cutting, engraving, and marking, the intense heat generated by the laser beam vaporizes materials like metal, plastic, or acrylic. This process releases microscopic smoke particles, dust, and harmful gases — including…