In the pulse of modern industrial production, processes such as welding, laser cutting, and grinding create value while also generating visible and invisible byproducts—industrial fumes and hazardous gaseous pollutants. These fine particulate matters, often smaller than 20 microns in diameter, escape the naked eye yet can travel deep into the…

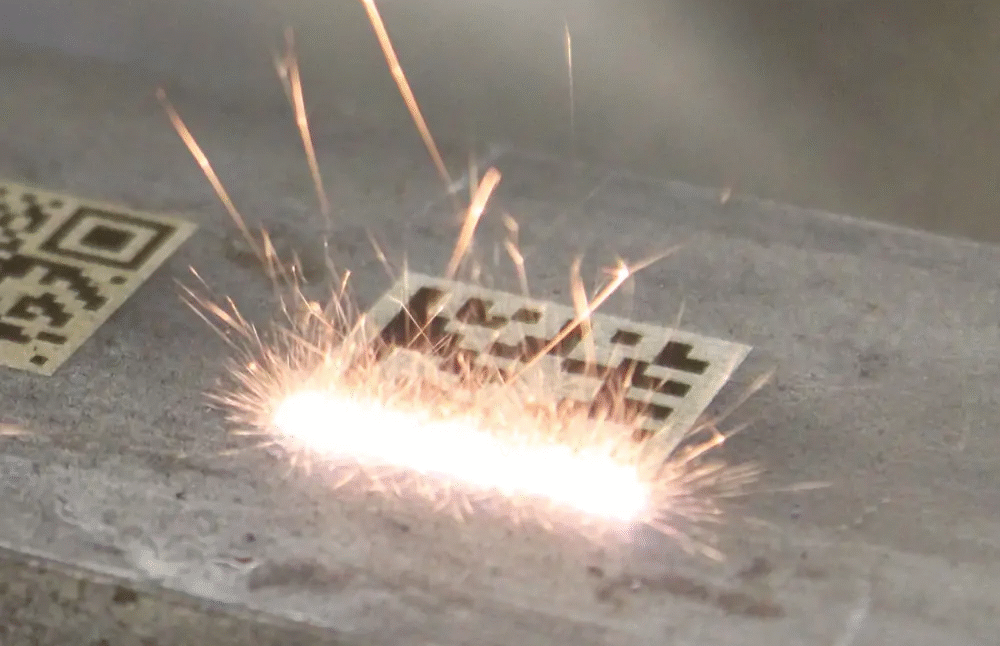

Laser cleaning has rapidly become one of the fastest-growing surface-treatment technologies in modern manufacturing. With advantages such as precision removal, zero consumables, and environmentally friendly operation, it is now widely used in aerospace, automotive manufacturing, mold repair, cultural relics restoration, and metal processing. However, while laser cleaning eliminates chemical solvents…

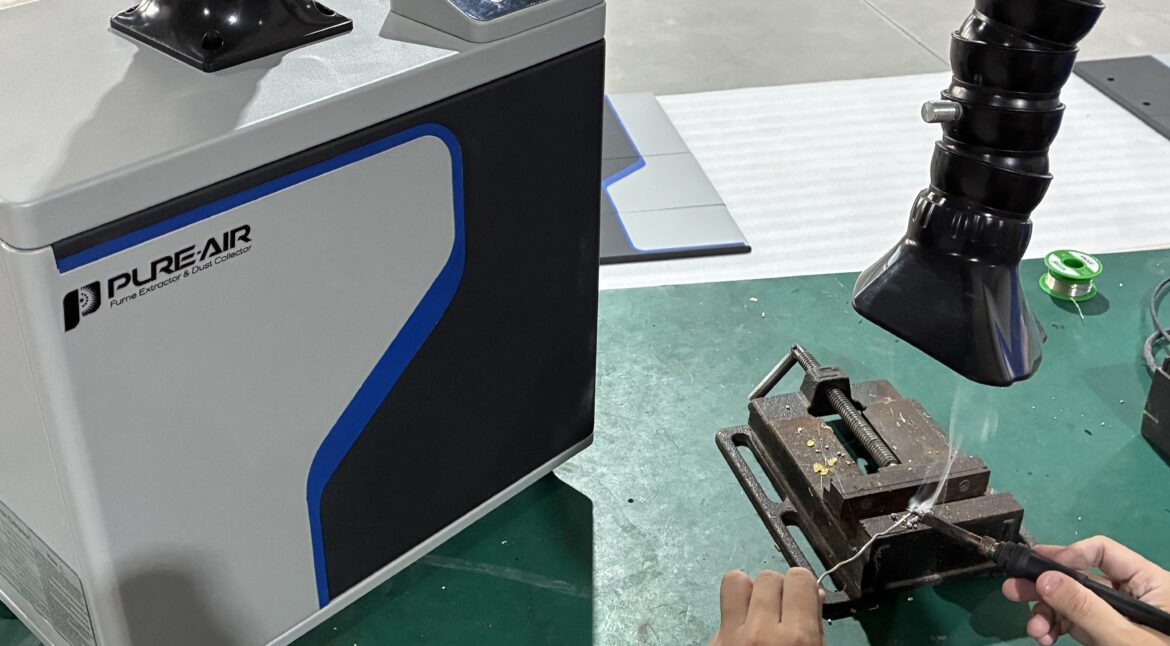

In modern manufacturing environments, processes like laser marking and electronics soldering have become essential to ensure precision, efficiency, and innovation. However, both processes generate harmful fumes, particulates, and chemical residues that can threaten operator health, product quality, and equipment longevity. At PURE-AIR, we provide advanced industrial fume extraction systems specifically…

Why Factories Need Laser Fume Extraction Systems Protecting Health, Equipment, and Compliance in Modern Manufacturing In today’s advanced manufacturing environment, laser technology is widely used in cutting, marking, welding, and engraving. While lasers bring higher precision and efficiency, the smoke and ultrafine dust released during processing can create silent but…