Poor design or under-investment in the dust collection and extraction system can translate into significant hidden costs—reduced equipment lifespan, compromised process accuracy, increased downtime, and higher maintenance bills. In this article, we analyse how improper dust extraction in laser cutting environments affects operations at multiple levels and guide industrial dust collection systems for laser-cutting factories.

1. The Hidden Threat of Inadequate Dust Collection in Laser Cutting Factories

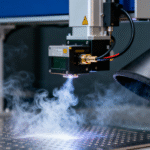

Laser cutting processes generate fine metallic particles, smoke, vapourised materials, and microscopic debris. As noted by industry sources: “Laser cutting produces a serious amount of dust… If this dust isn’t properly controlled, you could end up with expensive repairs to the laser or health and safety violations.”

When dust and particulates accumulate inside the enclosure and on optical components, several negative consequences emerge:

-

Optical surfaces, such as lenses and mirrors, suffer contamination and film build-up, which reduces beam transmission and causes scattering.

-

Laser beam path distortion leads to degraded cut quality, slower throughput, and increased scrap.

-

Mechanical and electronic components of the cutter—sensors, drives, rails—are exposed to abrasive dust, corrosive residues, or conductive particulate deposits.

-

Filter systems become overloaded or inefficient, increasing energy consumption, reducing suction capacity, and ultimately causing system breakdown.

-

Because the dust remains uncontrolled, the factory may face air quality compliance issues and worker health hazards.

In short, neglecting dust extraction is not just a housekeeping concern—it directly undermines production efficiency, equipment ROI, and factory reliability.

2. Mechanisms: How Poor Dust Collection Shortens Laser Cutter Lifespan

2. Mechanisms: How Poor Dust Collection Shortens Laser Cutter Lifespan

To understand why a weak dust collection system shortens equipment life, we must examine the mechanisms at work:

2.1 Optical Degradation and Beam Quality Loss

When airborne dust settles on laser optics, the beam energy is partially absorbed or scattered, which reduces effective power at the cut zone. Over time, this leads to reduced cutting speed, incomplete penetration, or rougher edges. As one report states: “…dust from laser cutting can be so thick that it can diffuse the beam. This reduces intensity and interferes with the process.”

Repeated rework, increased heat load, and higher power settings accelerate wear on optical components, shorten the lifespan of lenses/reflectors, and amplify maintenance costs.

2.2 Mechanical & Electronic Component Wear

Dust that is not captured at source can circulate through the machine’s enclosure and settle on mechanical parts: guide rails, bearings, motor housings, and control boards. Metallic dusts may be conductive, corrosive, or abrasive. Evidence shows that tube-laser cutting operations generate significant dust at clamp and feeding points.

Thus, poor extraction can cause premature failure of drives, encoders, sensor optics, and even cause micro-short circuits or motor stalls—reducing the machine’s operational lifespan.

2.3 Filter and Airflow System Overload

Dust collection systems designed with insufficient capacity or poorly maintained will eventually lose performance. For example, one guide suggests that improper sizing of dust collection leads to dust build-up in the enclosure faster than the collector can remove it.

When airflow drops or pressure drop increases, the laser cutter’s enclosure may no longer maintain the required negative pressure or contaminant removal rate, leading to higher ambient particle levels and increased risk of system shutdowns or safety trips.

2.4 Health, Safety, and Compliance Risks

Beyond equipment wear, unchecked dust has serious occupational health implications. Many metal cutting dusts contain harmful elements like chromium, nickel, or manganese. These hazards can lead to worker exposure, regulatory non-compliance, and costly plant shutdowns or fines. Such events indirectly impact equipment uptime, procurement cost, and the total cost of ownership (TCO) for the cutting system.

3. Quantifying the Cost of Neglect in Laser Cutting Operations

From the vantage point of procurement and factory engineering, poor dust collection has quantifiable cost elements:

-

Increased Maintenance & Consumable Costs: Frequent cleaning and replacement of optics, lenses, mirrors, and filters drive up OPEX.

-

Reduced Throughput / Higher Scrap Rate: Lower beam quality means slower cuts or more rejects; this increases cost per part and reduces production efficiency.

-

Shortened Machine Life / Early Replacement: The usable life of laser cutting machines may shorten by several years if internal components are compromised by dust exposure.

-

Downtime and Unplanned Repairs: When airflow or enclosure performance drops, the machine stops for cleaning or safety checks, causing lost production hours.

-

Compliance and Liability Costs: Fines, remediation, worker health issues, and reputational damage all increase the indirect cost burden.

According to one industry article: “A laser cutting dust collector can improve air quality, extend equipment lifespan, and boost productivity by 50%.” For that indicates the positive flip side of investing in proper dust collection: the cost of not doing it is very real.

4. Key Design Criteria for Dust Collection Systems in Laser Cutting Factories

When procuring dust collection systems for laser cutters in a factory, key technical criteria must be addressed. The following checklist is critical:

4.1 System Capture and Enclosure Design

-

Ensure source-capture hoods or enclosed cutting cells that minimise escape of particulates into the ambient space.

-

Design sufficient airflow to evacuate dust and fumes before they settle inside the machine. One article recommends sizing the extractor to match the cutter’s output.

-

Maintain proper ductwork design (minimal bends, good static pressure management) and a negative pressure environment to avoid leaks.

4.2 Filtration Media and Capacity

-

Filtration must capture both coarse particulates (metal splatter) and fine sub-micron dust. HEPA or high-efficiency cartridge filters may be required.

-

Variable frequency drives (VFDs) help maintain airflow while optimising energy usage.

-

Modular design allows filter media replacement without full system downtime.

4.3 Monitoring, Maintenance, and System Life

-

Integrate pressure drop sensors, differential flow monitoring, and filter saturation alerts to anticipate maintenance.

-

Document maintenance intervals and provide rapid access for replacement filters and service. One source states that many systems fail because the installer overlooked ongoing filter cost and service.

-

Create planned maintenance workflows aligned with machine usage, so the dust-collection system remains effective throughout machine life.

4.4 System Integration and Total Cost of Ownership

-

Ensure that the dust collection system syncs with the laser cutter operation (start/stop coordination) to avoid unnecessary run time and wear.

-

Evaluate the total cost of ownership (TCO), which includes filter replacement, energy consumption, downtime cost, and scrap rate reduction. A well-designed system delivers ROI not just via equipment protection but through productivity gains.

5. Practical Case: How Neglect Impacts Real-World Laser Cutting Environments

5. Practical Case: How Neglect Impacts Real-World Laser Cutting Environments

In a typical sheet-metal laser cutting facility, a 4kW fibre laser operates at high speed. If the dust/particulate removal system is undersized:

-

Particles suspended in the air can absorb part of the laser beam energy, reducing effective power at the cut edge.

-

As cutting speed drops or penetration becomes inconsistent, operators may increase laser power, which shortens component and optics life.

-

Dust deposits inside the cutting chamber may require daily manual cleaning. That cleaning interrupts production and increases labor costs.

-

Over a year, shortened mirror and lens life may force a mid-cycle replacement, costing tens of thousands of dollars and machine downtime.

-

The dust collector filters may clog prematurely, reducing airflow and causing the cutter to trip or slow down automatically. As one industry provider warns, “If this dust isn’t properly controlled… You could end up with expensive repairs to the laser.”

By contrast, companies that invest in properly sized, well-maintained dust collection systems often report extended equipment life, less scrap, and higher uptime. One data point: productivity boost of up to 50 % when dust control was adequate.

Conclusion

In summary, the cost of neglecting proper dust collection in laser cutting factories is substantial. From optical degradation and mechanical wear to increased maintenance, higher scrap rates, and shortened equipment life, the impacts are real, measurable, and avoidable.

By designing and implementing a robust dust collection system with proper capture, filtration, monitoring, and maintenance, manufacturers secure longer machine life, higher productivity, lower total cost of ownership, and safer work environments. For high-precision laser cutting operations in metal fabrication, electronics, automotive, or aerospace sectors, investing in an effective dust collection solution is not just compliance: it is a strategic decision that protects your capital investment, allows consistent throughput, and reflects a commitment to operational excellence.