Why High Negative Pressure Matters in Fume Extraction

Introduction

In industrial environments, effective fume extraction is not determined by airflow volume alone. One of the most critical—and often misunderstood—factors is high negative pressure. Many standard ventilation systems fail to capture hazardous fumes efficiently because they cannot maintain stable suction under real industrial conditions.

High negative pressure is essential for capturing smoke, fine particles, and harmful gases at the source, especially in processes such as laser cutting, welding, soldering, and engraving. As a professional industrial fume extractor manufacturer with over 14 years of R&D and production experience, PURE-AIR integrates high negative pressure fan systems into every industrial-grade solution to ensure reliable and consistent performance.

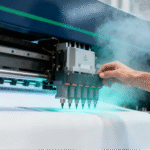

Image suggestion:

Industrial fume extractor operating in high-smoke manufacturing environment

What Is High Negative Pressure in Fume Extraction?

Negative pressure refers to the suction force that pulls contaminated air into a fume extraction system. High negative pressure means the system can generate strong and stable suction even when faced with:

-

Long ducting systems

-

Fine and dense smoke

-

Complex filtration stages

Unlike low-pressure ventilation fans, high negative pressure systems are specifically designed for industrial pollutant capture at the source, rather than simply moving air within a room.

Image suggestion:

Diagram illustrating airflow and pressure inside a fume extraction system

High Negative Pressure vs High Airflow: Understanding the Difference

Many users mistakenly focus only on airflow (measured in m³/h or CFM). However, airflow without sufficient pressure quickly drops once filters become loaded or ducting is extended.

| Parameter | High Airflow Only | High Negative Pressure |

|---|---|---|

| Capture efficiency | Unstable | Consistent |

| Performance over distance | Weak | Strong |

| Fine particle handling | Limited | Excellent |

| Filter resistance tolerance | Low | High |

A well-designed industrial fume extractor must balance airflow and pressure, with pressure being the decisive factor in demanding applications.

Why High Negative Pressure Is Critical in Industrial Applications

1. Effective Source Capture

Industrial fumes disperse rapidly once released. High negative pressure ensures that contaminants are captured immediately at the emission point, preventing them from spreading into the workspace.

Image suggestion:

Source capture arm extracting smoke directly from laser processing area

2. Stable Performance with Multi-Stage Filtration

Industrial fume extractors rely on multi-stage filtration systems, which naturally create airflow resistance. High negative pressure fans are engineered to overcome this resistance while maintaining consistent suction.

Without adequate pressure:

-

Airflow drops

-

Filtration efficiency decreases

-

System performance becomes unstable

3. Reliable Operation with Long Ducting

In many factories, fume extractors are connected to extended ducting systems or multiple workstations. High negative pressure is essential to compensate for pressure loss across bends, hoses, and filters.

4. Enhanced Fine Particle and Smoke Removal

Fine smoke particles and ultra-fine contaminants require strong suction to be effectively captured. High negative pressure systems significantly improve removal efficiency for particles smaller than 1 micron.

How PURE-AIR Designs High Negative Pressure Systems

PURE-AIR develops and manufactures its own high negative pressure fan units, optimized for industrial fume extraction.

Key Design Features:

-

High-efficiency centrifugal fan structure

-

Precision-balanced impellers

-

Industrial-grade motors for continuous operation

-

Optimized airflow paths to minimize pressure loss

Combined with the PIPS Intelligent Purification System, PURE-AIR fume extractors automatically maintain optimal performance under varying working conditions.

Image suggestion:

High negative pressure centrifugal fan used in industrial fume extractor

Common Applications Requiring High Negative Pressure

High negative pressure fume extraction is essential for:

-

Laser cutting and engraving

-

Welding and metal fabrication

-

Soldering and electronics manufacturing

-

Chemical processing and composite materials

In these environments, standard ventilation systems are insufficient to control hazardous emissions effectively.

Choosing the Right High Negative Pressure Fume Extractor

When evaluating a fume extraction system, consider:

-

Required negative pressure rating

-

Type and density of pollutants

-

Filter configuration and resistance

-

Ducting length and layout

A professional manufacturer can assess these factors and provide a solution tailored to actual operating conditions.

Conclusion

High negative pressure is not an optional feature—it is a fundamental requirement for effective industrial fume extraction. Without sufficient pressure, even high airflow systems fail to capture hazardous pollutants consistently.

PURE-AIR’s industrial fume extractors are engineered around high negative pressure principles, ensuring reliable source capture, stable filtration performance, and long-term operational efficiency.